45-400 Aluminum Screw Caps

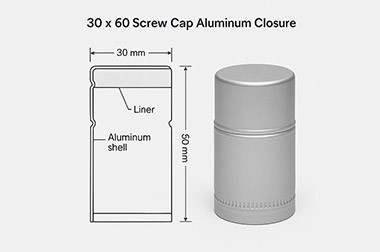

The 45-400 aluminum screw cap is a common type of metal sealing bottle cap, primarily made from high-strength aluminum alloy. The "45" in its name typically indicates a nominal diameter of 45 millimeters, while "400" represents the thread type as a single-turn thread.

The 45-400 aluminum cap forms a reliable seal through its screw-on structure that fits tightly with the bottle neck. Its basic structure includes the cap body, inner liner sealing gasket, and the threaded portion. Some high-end products may also feature tamper-evident rings or other special designs.

Compared to plastic caps, aluminum screw caps offer clear advantages: they not only perform well but are cost-effective, non-polluting, and recyclable. Aluminum caps are typically produced on highly automated production lines. Common alloy tempers used include 8011-H14 and 3003-H16, with material specifications usually in the thickness range of 0.20mm to 0.23mm and width range of 449mm to 796mm.

The production of 45-400 aluminum screw caps generally involves advanced stamping and drawing processes. First, aluminum sheets are cut to appropriate sizes. Then, a punching machine forms the basic shape of the cap, followed by drawing, spinning, and other processes to achieve the final screw cap form.

In terms of material selection, commonly used aluminum alloys include 8011, 3003, 3104, and 3105. Among them, 8011 aluminum alloy features excellent formability and corrosion resistance, making it an ideal material for cap manufacturing; 3003 aluminum alloy, with added manganese, offers better anti-rust properties.

45-400 Aluminum Caps Dimensions and Specifications

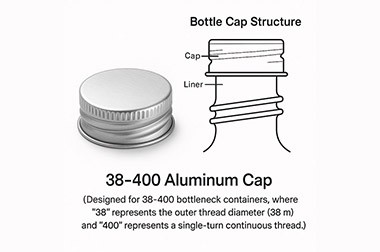

The "45" in the 45-400 aluminum screw cap indicates its nominal diameter of 45mm, referring to the external diameter of the threaded section. The following are its standard dimension parameters and customization options:

45-400 Aluminum Caps Standard Dimension Parameters

| Parameter | Specification |

| Nominal Diameter | 45 mm, allowable tolerance ±0.30 mm |

| Height | Common height specifications: 13.5mm, 15mm, 17.3mm |

| Thread Specification | "400" indicates a single-turn thread, which is relatively fine with a typically higher neck |

| Liner Dimensions | Liner thickness: 0.28mm~0.30mm (PE liner) Liner width: 9.0mm~10.45mm |

| Material Specification | Cap thickness: 0.20mm~0.23mm Aluminum coil width: 449mm~796mm |

45-400 Aluminum Caps Dimensional Tolerance and Precision Requirements

The dimensional tolerance of 45-400 aluminum screw caps is strictly controlled to ensure good fit with the bottle neck:

- Diameter tolerance: typically within ±0.30 mm

- Height tolerance: height dimension h1 tolerance is ±0.10 mm

- Thread precision: threads should be clear, complete, and free of burrs or deformation

- Concentricity: all parts of the cap should maintain good concentricity to ensure uniform sealing

45-400 Aluminum Caps Custom Size Options

In addition to standard sizes, many manufacturers offer custom sizing services, allowing the following parameters to be adjusted based on customer requirements:

- Diameter adjustment: diameter size can be adjusted within a certain range to fit specially designed bottle necks

- Height adjustment: cap height can be modified based on product characteristics and packaging design

- Thread type: besides the standard 400 single-turn thread, other types like 410 (1.5-turn thread), 415 (two-turn thread) are also available

- Special shapes: custom shapes such as tear-off tabs or easy-open caps can be designed on request

45-400 Aluminum Caps Color Options

45-400 aluminum screw caps are available in a variety of colors, ranging from standard metallic shades to custom tones, meeting the personalized needs of different industries and brands.

Standard Color Options

Standard colors are mostly metallic, including natural silver (raw aluminum color) and matte silver. These basic tones suit most conventional packaging needs. Especially in the food, beverage, and pharmaceutical sectors, the clean and professional look of metallic colors is often associated with high quality.

Custom Color Services

In addition to standard colors, most manufacturers offer extensive custom color services. With advanced printing and coating techniques, 45-400 aluminum screw caps can achieve a wide range of color options:

- Black Series: from solid black to matte black and brushed black, e.g., 24/410 matte black anodized aluminum screw cap

- Gold Series: including bright gold, champagne gold, rose gold, etc., e.g., 28-tooth gold anodized aluminum screw cap

- Color Series: precise color matching based on Pantone color cards or customer-provided samples to fulfill personalization needs

- Special Effects: such as pearlescent, fluorescent, metallic sparkle, etc., enhancing product visual impact

-

White Aluminum Screw Cap

-

Red Aluminum Screw Cap

-

Silver Aluminum Screw Cap

-

Dark Green Aluminum Screw Cap

-

Blue Aluminum Screw Cap

-

Gold Aluminum Screw Cap

-

Pink Aluminum Screw Cap

-

Orange Aluminum Screw Cap

-

Purple Aluminum Screw Cap

-

Green Aluminum Screw Cap

-

Yellow Aluminum Screw Cap

Surface Treatment Techniques

To ensure lasting color and quality, 45-400 aluminum screw caps typically undergo the following surface treatments:

- Coating Treatment: common combinations include outer white/inner yellow coatings, with customized internal and external coatings available upon request

- Anodizing: creates an oxide film on the aluminum surface through electrochemical means, enhancing wear and corrosion resistance, and allowing dyeing

- Silk Screen and Offset Printing: uses specially formulated inks to print detailed patterns and text on the cap surface, offering strong adhesion and fade resistance

- Hot Stamping: transfers metallic foil to the cap surface using heat and pressure to achieve a premium metallic sheen

45-400 Aluminum Caps Liner Types

The choice of liner material directly affects the sealing performance and applicable scenarios of the 45-400 aluminum screw cap. Below are common liner types and their characteristics:

Food-Grade Liner Materials

- PE (Polyethylene) liner: This is the most common liner material, offering good flexibility and sealing performance. It is resistant to general acids and alkalis, safe, non-toxic, and compliant with food hygiene standards. PE liner thickness typically ranges from 0.28mm to 0.30mm.

- Silicone sealing liner: Offers excellent elasticity and high-temperature resistance, maintaining good sealing performance over a wide temperature range. It is particularly suitable for products requiring high-temperature sterilization. Silicone liner thickness is generally around 1mm.

- EVA (Ethylene-Vinyl Acetate Copolymer): Features good elasticity and low-temperature toughness, excellent sealing performance, and no odor, making it an ideal choice for food packaging.

Special-Purpose Liners

For specific application scenarios, the 45-400 aluminum screw cap can also provide the following special liner materials:

- Corrosion-resistant liner: Made of polytetrafluoroethylene (PTFE) or other corrosion-resistant materials, suitable for packaging chemical reagents, pharmaceuticals, and other corrosive liquids.

- Permeation-resistant liner: Multi-layer composite structure effectively prevents liquid or gas permeation, extending product shelf life.

- Heat-seal liner: The liner material melts upon contact with a certain temperature, forming a seal with the bottle mouth for added leak protection.

- Pressure-sensitive liner: Coated with pressure-sensitive adhesive; when the cap is tightened, the adhesive layer bonds tightly with the bottle mouth, forming a high-sealing barrier.

Liner Design and Performance Requirements

High-quality liners should meet the following performance requirements:

- Sealing: The liner material should have good elasticity and toughness to ensure a tight fit with the bottle mouth.

- High temperature resistance: Must withstand temperatures up to 121°C or higher without deformation or discoloration.

- Chemical stability: Should not react with contents or affect product quality.

- Opening force: Must provide sufficient sealing strength while remaining easy for consumers to open.

- Hygiene and safety: Liner materials must comply with relevant food safety standards.

Advantages of 45-400 Aluminum Screw Caps

- Material advantages: Lightweight and high-strength, excellent corrosion resistance, recyclable, and environmentally friendly.

- Sealing performance: A variety of liner material options ensure excellent sealing, preventing leakage and spoilage.

- Aesthetic diversity: Rich color options and surface treatment processes meet different branding and visual requirements.

- Safety and reliability: Well-designed structure with moderate opening force ensures both sealing and ease of use.

- Strong adaptability: Custom solutions available based on different industries and product characteristics.

Applications of 45-400 Aluminum Caps

Applications in the Food and Beverage Industry

The 45-400 aluminum screw cap is widely used in the food and beverage industry:

Bottled water and beverages: Including mineral water, juices, and functional drinks. For example, the French brand "Evian" uses molded-liner aluminum screw caps. These caps effectively prevent microbial contamination and extend product shelf life.

Alcoholic beverages:

-

Beer: Brands like Blue Ribbon and Li Quan Beer use molded-liner aluminum screw caps.

-

Pre-mixed drinks: For example, Thailand’s "Nite" pre-mixed alcohol uses molded-liner aluminum screw caps.

-

Sparkling wine: Some products, such as ladies’ champagne, use twist-off aluminum screw caps made from high-strength Taiwanese imported sheets to ensure safety.

Condiments: Such as soy sauce, vinegar, and liquid seasonings. The sealing performance of aluminum screw caps helps prevent oxidation and spoilage of the product.

Canned foods: Including fruit, vegetable, and meat canned goods. Aluminum screw caps can withstand high-temperature sterilization to ensure product safety.

Cosmetics and Personal Care Products

In the cosmetics and personal care sector, the 45-400 aluminum screw cap is favored for its aesthetics and sealing properties:

- Skincare packaging: Used for products like creams, lotions, and serums. Aluminum screw caps provide excellent sealing, preventing oxidation and deterioration.

- Perfumes and fragrances: Aluminum screw caps effectively prevent fragrance evaporation, maintaining long-lasting scent.

- Bath and body care products: Such as shower gel, body lotion, and scrubs. The design of aluminum screw caps helps prevent leakage under pressure and offers convenience in carrying and usage.

- Toothpaste and oral care products: Aluminum screw caps offer good sealing to prevent drying and spoilage.

Pharmaceutical and Healthcare Industry

In the pharmaceutical and healthcare sector, the 45-400 aluminum screw cap is applied in:

- Pharmaceutical packaging: For liquid medicines such as oral solutions, syrups, and tinctures. Aluminum screw caps provide sealing and moisture resistance to ensure drug quality and effectiveness.

- Health supplement packaging: Such as vitamins and fish oil. Aluminum screw caps offer good protection against oxidation and deterioration.

- Medical equipment: Certain medical devices and instruments use aluminum screw caps as components for their corrosion resistance and mechanical strength.

Industrial and Special Applications

Beyond consumer goods, the 45-400 aluminum screw cap is also widely used in industrial and special applications:

- Chemical packaging: Suitable for various liquid chemicals such as solvents, cleaners, and lubricants. Aluminum screw caps offer excellent corrosion resistance and sealing to prevent leaks and evaporation.

- Automotive products: Used for packaging car air fresheners, essential oils, and solid perfumes. Aluminum screw caps provide sealing and aesthetic appeal.

- Agriculture and gardening: Applied in liquid products such as pesticides, fertilizers, and plant growth regulators. Aluminum screw caps prevent leaks and contamination.

- Electronics and precision instruments: Some electronic components and precision instrument packaging also use aluminum screw caps for their anti-static and shielding properties.

Selection Guide for 45-400 Aluminum Caps

Choosing the right 45-400 aluminum screw cap should consider the following factors:

Product Characteristics

- Nature of the contents (liquid, semi-solid, etc.)

- Whether high-temperature sterilization is required

- Whether the content is corrosive

- Storage conditions and shelf life requirements

Packaging Requirements

- Bottle neck size and shape

- Appearance and design requirements

- Desired opening method

- Transportation and storage conditions

Cost Considerations

- Cost differences between standard and customized products

- Minimum order quantity requirements

- Price advantages for long-term cooperation

Certification Requirements

- Food safety certifications (such as FDA, LFGB, etc.)

- Industry-specific certifications

- Environmental certifications (e.g., recyclable materials certification)

With its outstanding performance and diversified options, the 45-400 aluminum screw cap plays a vital role in the packaging field. By appropriately selecting the color, liner, size, and surface treatment process, it provides a perfect packaging solution for a wide range of products, meeting the needs of various industries and application scenarios.

The following bottle caps may interest you

Further reading : Aluminum ROPP CapBeer Aluminum Anti-counterfeiting Bottle CapLiquor Aluminum CapWhite Aluminum Bottle CapAluminum roll-printing and milling anti-counterfeiting bottle capWine Aluminum CapROPP Aluminum Caps for WaterBeverage Bottle Aluminum CapAluminum Caps for VinegarVodka Bottle Aluminum CapsBlack Aluminum Bottle CapRum Aluminum Screw Caps 30x35mmOlive Oil Aluminum CapAluminum Cap for Whiskey Alcohol Spirit Glass Bottle31.5x24mm embossing and milling Aluminum Cap for Alcohol Whisky VodkaAluminum Bottle Cap 30x60mm for Wine and Spirits Bottles30x35mm Aluminum Bottle Cap for Spirits and Alcoholic Beverages30x43mm Wine Aluminum Cap25x43mm Aluminium Pilfer Proof Bottle Cap30x44mm Aluminum Bottle Cap for Spirits28x18mm Aluminium Closure30x35mm Aluminium ROPP Cap30x60mm Hot Stamping Cover Wine Bottle Lids - Alcohol Whiskey Vodka Aluminum Bottle Cap28mm Beverage Drinks Aluminum Cap38mm Beverage Drinks Aluminum CapBeer Aluminum Bottle CapAluminum anti-counterfeiting bottle capPull-Off Aluminum Bottle CapTamper-Evident Aluminum Bottle Cap28mm Aluminum ROPP Cap28mm Aluminum Cap28x18mm aluminum bottle cap for Vodka28x18mm Aluminium Ropp Cap38mm Aluminum ROPP Cap38mm Aluminum Cap28mm Black Aluminium ROPP Tamper Evident Screw Cap with EPE Liner28mm Silver Aluminium ROPP Cap with Liner28mm 28-400 Aluminum Metal Cap with Pulp & Poly Liner28mm/410 Aluminium Cap with EPE Liner28x15mm Aluminium ROPP Cap26mm 42mm Ring Pull Aluminum Cap30x60mm Aluminum Vodka Tequila Caps30x60mm Aluminum ROPP Caps for Wine Glass BottlesPull Ring Easy Open Aluminum Crown Caps30×60 mm Aluminum ROPP Caps for Whiskey Glass Bottles250 ml Bottles 28×15 mm MCA Aluminum CapsBlue Aluminum Caps33x47mm Side Emboss Aluminum LidsAluminium Pilfer Proof Caps28mm Black Aluminum Screw Top Cap30 x 35 EPE tin liner ROPP Closures30x60mm Aluminum CapAluminium ROPP (18x12)18mm ROPP Aluminum Caps22mm Aluminium Ropp Caps25mm Aluminium Ropp Caps31.5 mm ROPP Aluminum Cap46 mm ROPP Aluminum Cap53 mm ROPP Aluminum CapColored ROPP Aluminum CapsPrinted ROPP Aluminum Caps33x58 Pilfer-Proof ROPP Aluminum Cap38x18mm Aluminum ROPP CapRed 28mm ROPP Aluminum ClosureBrushed aluminium screw caps