28mm Aluminium Screw Cap

28mm aluminum screw caps are sealing closures specifically designed for threaded neck bottles, widely used in the beverage, cosmetics, and pharmaceutical industries to provide reliable sealing and tamper-evident functionality.

Advantages of aluminum caps: strong corrosion resistance, high mechanical strength, lightweight, recyclable, and aligned with modern environmental concepts.

The 28mm aluminum screw cap, with standardized dimensions (28mm thread diameter), high-strength aluminum alloy materials (such as 8011-H16), and diverse designs (such as break-off type and flanged type), demonstrates excellent sealing performance, tamper resistance, and compatibility. Customization options (such as height and surface treatment) meet the stringent packaging demands of the beverage and pharmaceutical sectors.

28mm aluminum screw caps are usually made from high-quality aluminum alloy materials, with commonly used grades including 8011, 3003, 3105, and 1060. These alloys offer good stamping performance and surface treatment characteristics, capable of meeting the requirements of high-speed automated production lines.

HC Aluminum 28mm aluminum screw caps are designed with a continuous thread (CT) and are compatible with 28-400 specification bottle necks, ensuring reliable engagement with glass and plastic bottles for effective sealing. The cap body is typically made from brushed or smooth aluminum, making it durable and high-end in appearance. The inner part of the cap features a compressible liner, typically made from polyethylene (PE) foam or expanded polyethylene (EPE), providing leak-proof, chemical resistance, and preservation functions. Additionally, tamper-evident bands and breathable designs are available to meet higher safety or pressure balance requirements. These caps are widely used in food and beverage, cosmetics, pharmaceutical, and specialty packaging industries, and can be customized with colors, embossed logos, printing, or even a center hole for injectable products.

The 28mm aluminum screw cap is made from high-quality aluminum, offering a lightweight structure, corrosion resistance, and durability. The aluminum's natural resistance to oxidation makes it ideal for environments exposed to moisture, chemicals, or outdoor conditions. It is non-magnetic, has good thermal conductivity, and can undergo anodization to enhance surface hardness or create custom color finishes.

- Aluminum alloy: lightweight, durable, corrosion-resistant, and well-suited for harsh environments (such as marine or chemical environments). It is recyclable and offers an excellent strength-to-weight ratio.

- Surface treatment options: anodizing (customizable colors, enhanced UV/scratch resistance), powder coating, spray painting, or natural polishing.

HC Bottle Cap Manufacturing Co., Ltd. has over 17 years of experience providing various aluminium caps, plastic caps, aluminium-plastic caps, glass bottles, and other packaging products. Our products are sold to more than 20 countries worldwide, including the United States, Europe, South Africa, Southeast Asia, and more.

28mm Aluminium Screw Caps Thread Types

-

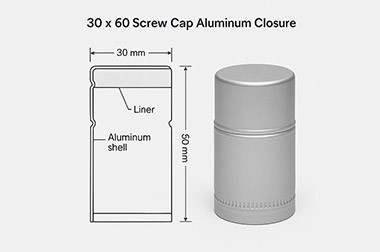

28-400 Aluminum Bottle Caps

Continuous thread design, approximately 30.3mm in outer diameter and 10.3mm in height. Widely used for standard glass and plastic bottles.

-

28mm (R3) Aluminium Screw Cap

R3 thread, also known as PP28 or Pilfer 28 thread, conforms to R3 thread specifications and is suitable for various glass syrup bottles, long-neck bottles, and PET bottles.

-

DIN 28/410 Aluminum Bottle Caps

DIN 28/410 threads are commonly used for cough syrup glass bottles and are among the most prevalent thread types in the 28mm bottle neck system.

-

28mm ROPP Aluminum Screw Cap

ROPP (Roll On Pilfer Proof) threads are tamper-evident thread designs that leave visible signs after the cap is opened, effectively preventing product tampering.

Thread Standards and Specifications

The thread designs of 28mm aluminum caps typically follow the standards below:

- ISO 8362 Standard: An internationally recognized thread standard for bottle caps, specifying thread dimensions and tolerance requirements for different cap sizes.

- BB/T 0034-2017 Standard: A Chinese industry standard for aluminum pilfer-proof caps, specifying thread specifications, technical requirements, and test methods.

- GB/T 14803 Standard: A national standard of China specifying technical requirements for break-off aluminum pilfer-proof caps, including parameters for thread fitting.

28mm Aluminium Screw Cap Specifications

HC Aluminum 28mm Aluminium Screw Caps Product Details

| Item | Detailed Specifications & Description |

| Diameter | Outer diameter 28mm (standard); inner diameter/thread diameter customizable according to the application. |

| Height | Varies by design, typically 10–20mm; customization available. |

| Thread Type | Internal thread, compatible with 28mm external neck; pitch customizable (standard metric or proprietary threads). |

| Bottle Neck Treatment & Thread | Standardized 28mm (28-400) continuous thread; compatible with industry-standard bottle neck treatments; skirt with continuous ribs for improved grip during opening/closing. |

| Compatible Bottle Neck | Suitable for glass bottles, PET bottles, etc. |

| Skirt and Top Profile | Skirt: ribbed or smooth profile options; Top: flat or slightly domed to meet different aesthetic preferences. |

| Center Hole Variant | Specialized roll-on-style screw caps can include a 12mm center hole, used for injectable vials in the pharmaceutical field. |

| Cap Material | Lightweight, corrosion-resistant aluminum alloy; surface commonly brushed or spray-painted in gold, black, copper, etc., with color customization available. |

| Liner Type | PE foam (Polyethylene): compressible, chemically resistant, providing a general-purpose seal. |

| EPE (Expanded Polyethylene): enhances preservation, prevents leakage, widely used in food and personal care product bottles. | |

| Induction seal film: for tamper-evident or hermetic sealing, available as an accessory. | |

| Surface Treatment Options | Anodizing (customizable colors, enhanced UV and scratch resistance) |

| Powder coating | |

| Spray painting | |

| Natural polishing | |

| Grip Design | Knurled or ribbed edges, anti-slip design |

| Smooth edge option, balancing aesthetics and practicality | |

| Sealing Mechanism | Optional integrated EPDM (Ethylene Propylene Diene Monomer), silicone, or rubber gasket for air-tight/water-tight seals. |

| Optional tamper-evident band or liner to enhance security. | |

| Cap Design | Flat cap: suitable for labeling or engraving |

| Domed cap | |

| Customizable embossed logos | |

| Durability | Resistant to deformation, high temperatures (suitable for high-pressure sterilization/thermal filling processes), chemicals, and more. |

The company relies on a strictly controlled production process to produce high-quality bottle caps. HC Bottle Cap Manufacturing Co., Ltd. ensures that each cap meets international standards in appearance, performance, and quality, fulfilling various customer needs and providing superior packaging solutions.

Common Height Range of 28mm Aluminum Screw Caps

The height of 28mm aluminum caps varies depending on usage and design. Common height ranges include:

-

Standard Height

Approximately 13mm, this is the typical height of R3 thread caps, with a low-profile design.

-

Common Range

Between 11mm and 20mm. For example, the AC1055 specification has a size of 28mm × 17mm.

-

Special Specifications

Some specially purposed caps can reach up to 21mm or higher in height. Specific dimensions are customized according to customer requirements.

Detailed Dimensional Specifications of 28mm Aluminum Screw Caps

According to different standards and application scenarios, the specific dimensional specifications of 28mm aluminum caps are as follows:

| Model | Outer Diameter (mm) | Height (mm) | Thread Type | Applicable Containers |

| Standard 28mm | 28.0 | 13.0 | R3 | Glass syrup bottles, long-neck bottles |

| 28-400 | 30.3 | 10.3 | Continuous thread | Food and cosmetic bottles |

| AC1055 | 28.0 | 17.0 | Custom thread | Special purpose containers |

| 28×21 | 28.0 | 21.0 | DIN 28/410 | Pharmaceutical bottles, syrup bottles |

These dimensional parameters typically allow for certain tolerance ranges, with the outer diameter tolerance generally controlled within ±0.20mm and height tolerance within ±0.15mm.

Common Color Options for 28mm Aluminum Screw Caps

The surface colors of 28mm aluminum caps are diverse and mainly include:

-

Silver Aluminum Screw Cap

Maintains the natural color of aluminum, usually treated with polishing or matte finishing to present a silver-gray gloss.

-

Gold Screw Aluminum Cap

Includes rose gold, champagne gold, and luxury gold, achieved through electroplating or spraying techniques.

-

Black Screw Aluminum Cap

Ranges from matte black to glossy black, commonly using baking paint or electrostatic spraying processes.

-

Color Series

Various colors can be customized according to the Pantone color chart to meet personalized brand requirements.

Surface Treatment Processes for 28mm Aluminum Screw Caps

To enhance the appearance and durability of aluminum caps, the following surface treatment processes are commonly used:

-

Painting/Baking Paint

Using spraying equipment to evenly apply one or more layers of coating to the cap surface, then curing at high temperatures to form a solid colored protective layer.

-

Electroplating

Using electrolysis to plate a layer of metal such as chrome, nickel, or copper onto the aluminum surface, not only changing the color but also enhancing wear and corrosion resistance.

-

Anodizing

Through electrochemical oxidation, forming an oxide film on the aluminum surface that can be dyed in various colors while improving surface hardness and corrosion resistance.

Types of Liners for 28mm Aluminum Screw Caps

28mm aluminum caps are usually equipped with various liners to enhance sealing performance and chemical compatibility:

PE Liner

- Features: Good flexibility and chemical resistance, non-toxic and odorless, moderately priced

- Applications: Food, beverages, and daily chemical packaging

- Temperature Range: -40℃ to +80℃

Butyl Rubber Liner

- Features: Excellent air-tightness and chemical resistance, extremely low permeability to water vapor and gases

- Applications: Packaging for pharmaceuticals, vaccines, and other products requiring high sealing integrity

- Temperature Range: -50℃ to +150℃

Silicone Liner

- Features: Excellent high and low-temperature resistance, non-toxic and odorless, good elasticity

- Applications: Food containers, medical supplies, high-end cosmetics, etc.

- Temperature Range: -60℃ to +200℃

28mm Aluminium Screw Cap Design Features

- Material: These caps are made from durable aluminium with a smooth metal finish, enhancing the product's aesthetics.

- Liner: The caps are equipped with EPE (Expanded Polyethylene) liners, ensuring a tight seal, maintaining product freshness, and preventing leaks.

- Design: The ribbed exterior provides a non-slip grip, making it easier to use and remove.

- Enhanced Grip: Knurled edge or smooth finish options for manual tightening or tool use (e.g., wrench flat).

- Compatibility: Suitable for bottles with a 28mm neck diameter, including various glass and plastic containers.

- Sealing Mechanism: Optional integrated O-ring groove or compression gasket (EPDM, silicone) for airtight/waterproof seals.

- Structure: Machined or die-cast with high precision; internal threads ensure secure fastening.

28mm Aluminium Screw Cap Applications

| Application | Description |

| Beverage Bottles | The 28mm aluminum screw cap is widely used to seal various beverage bottles, especially suitable for products like juice, soft drinks, etc. Its excellent sealing performance effectively prevents gas leakage and oxidation of the beverage, ensuring the product remains fresh and its taste unchanged. Its durability and corrosion resistance make it an ideal choice for long-term storage of beverages. |

| Water Bottles | The 28mm aluminum screw cap is commonly used for sealing water bottles, providing excellent sealing performance to prevent leakage and contamination. The cap has good pressure resistance and corrosion resistance, ensuring the purity of the water inside, especially suitable for bottled water products such as sports drinks and mineral water. |

| Essential Oils | The 28mm aluminum screw cap is an ideal choice for essential oil bottle packaging due to its good sealing effect and ability to prevent evaporation. The cap effectively prevents the essential oils from being affected by air, moisture, and sunlight, preserving the quality and fragrance. It is also suitable for small bottles of high-end essential oils and perfumes. |

| Food Coloring | The 28mm aluminum screw cap is used in food coloring bottles to ensure the stability and safety of the coloring agents. By providing a sealed protection, it prevents the coloring from being affected by moisture, contamination, or leakage, ensuring that the color and quality of the product are maintained for a long time. The cap can also withstand frequent opening and closing, making it suitable for food production and daily use. |

| Cosmetics Formulas | The 28mm aluminum screw cap is suitable for various cosmetic bottles, such as creams, lotions, and serums. Its sealing performance helps maintain the freshness and stability of the products, preventing air and bacterial contamination. Additionally, the elegant appearance of the aluminum screw cap enhances the packaging of high-end cosmetic products. |

| Pharmaceutical Liquids | The 28mm aluminum screw cap is an ideal choice for pharmaceutical liquid packaging, especially for medicinal syrups, medicinal solutions, or oral liquids. It provides efficient sealing protection, preventing air, moisture, or contaminants from entering the bottle, ensuring long-term stability and effectiveness of the medication. Moreover, the aluminum cap also meets hygiene and tamper-evident requirements, enhancing product safety. |

HC Strictly Controls the Quality of 28mm Aluminum Screw Caps

Dimensional Accuracy Control

The dimensional accuracy of 28mm aluminum screw caps directly affects their fit with bottle necks and sealing performance. Key control points include:

Outer Diameter Control: Using high-precision calipers or image measuring instruments to measure the cap's outer diameter, ensuring compliance with GB/T 14803 standard requirements and maintaining tolerance within ±0.1mm. Height Measurement: Using measuring tools with a precision of 0.02mm to measure cap height, ensuring the height tolerance is within the permissible range. Thread Fit: Using special thread gauges to inspect thread mating accuracy, ensuring smooth engagement with bottle threads without looseness.

Sealing Performance Testing

Sealing performance is a core quality indicator of 28mm aluminum caps. Main testing methods include:

Air Tightness Test: Using negative or positive pressure methods, the sealed container is placed in a sealed tester, pressure of 0.05–0.08 MPa is applied and held for 30 seconds, and any air bubble leakage is observed. Leakage Test: Using dye penetration or helium mass spectrometry to verify the sealing reliability of the cap under conditions such as inversion and vibration, meeting the leakage rate requirements of GB/T 17876. Instant Pressure Resistance Test: Ring-pull caps undergo an instant pressure test and must not leak when the pressure reaches 650 kPa.

Material and Process Control

Material quality and production process directly affect the performance and service life of the caps:

- Aluminum Composition Analysis: Using spectrometers to test the alloy composition of aluminum (e.g., grades 3004, 5052), controlling the content of elements like iron, magnesium, and manganese to ensure stamping performance and strength.

- Coating Adhesion Test: Conducting cross-cut adhesion tests (ASTM D3359 standard) to assess the bonding strength of the inner coating, requiring a grade of 4B or above.

- Corrosion Resistance Test: Simulating harsh environments with a salt spray chamber, performing 48-hour neutral salt spray tests according to GB/T 10125, and checking for surface oxidation, blistering, and other defects.

28mm Aluminum Screw Caps Compatibility

Compatibility with Glass Bottles

28mm aluminum screw caps are highly compatible with various glass bottles:

- Standard Threaded Glass Bottles: Fully compatible with 28mm threaded glass bottles conforming to GB/T 17449 standard, which is the most common combination.

- Syrup Bottles: 28mm aluminum caps, especially those with R3 thread design, fit perfectly with various glass syrup bottles.

- Wide-Mouth Bottles: Certain taller 28mm aluminum caps can be used with wide-mouth glass bottles, providing excellent sealing performance.

Compatibility with Plastic Bottles

28mm aluminum screw caps are also widely used with various plastic bottles:

- PET Bottles: 28mm aluminum caps pair well with PET plastic bottles and are commonly used in beverage and cosmetic packaging.

- HDPE Bottles: High-density polyethylene bottles combined with 28mm aluminum caps are often used for pharmaceutical and health product packaging.

- PP Bottles: Polypropylene bottles combined with 28mm aluminum caps are suitable for products requiring high-temperature resistance.

28mm Aluminum Screw Caps Production Process

Raw Material Preparation

The first step in producing 28mm aluminum screw caps is preparing suitable raw materials:

- Aluminum Coil Selection: Common aluminum alloys include 8011, 3003, 3105, and 1060. Choose the appropriate alloy and temper based on different applications.

- Material Inspection: Strict inspection of purchased aluminum coils, including thickness, width, surface quality, and mechanical properties.

- Slitting: Wide aluminum coils are slit into narrow strips suitable for stamping. Typical widths range from 449mm to 796mm, and thicknesses from 0.20mm to 0.23mm.

Stamping Process

Stamping is the core process in aluminum cap production:

- Flat Printing: Before stamping, the surface of the aluminum sheet is usually printed using specialized flat printing equipment.

- Multi-Stage Stamping: The aluminum sheet undergoes multiple stamping steps using presses and molds to gradually form the basic cap shape.

- Edge Trimming: The blank caps after stamping need edge trimming to ensure dimensional accuracy and edge quality.

- Curling and Skirt Forming: Specialized equipment is used to curl and form the skirt, shaping the final cap body.

Threading and Surface Treatment

Threading and surface treatment are key steps to enhance the performance and appearance of aluminum caps:

- Thread Rolling: Precise threads are formed on the inner wall of the cap using specialized thread rolling equipment to ensure a proper fit with the bottle mouth.

- Side Embossing: Some caps require embossed patterns or ridges on the sides to increase friction and aesthetic appeal.

- Surface Finishing: Various surface treatments are applied according to customer requirements, such as painting, electroplating, or anodizing.

28mm Aluminum Screw Caps Purchasing Advice

Material Selection Advice

Choosing the right material is fundamental to ensuring the quality of 28mm aluminum caps:

- Alloy Selection by Application: For food and beverage packaging, 8011 or 3105 alloys are recommended; for applications requiring higher strength, 3003 alloy is suitable.

- Temper Selection: Choose the appropriate temper (e.g., H14, H16) based on production processes and performance requirements.

- Material Thickness Control: The standard material thickness for 28mm aluminum caps typically ranges from 0.20mm to 0.23mm; special applications may require adjustments.

Quality Inspection Standards

Ensure quality inspection meets industry standards:

- Inspection Equipment: Verify the availability of essential inspection tools such as torque testers, airtightness testers, and salt spray testing chambers.

- Inspection Items: Key inspection items include dimensional accuracy, sealing performance, and opening torque.

- Inspection Standards: Ensure compliance with relevant national and industry standards such as GB/T 14803 and BB/T 0034.

How to Choose 28mm Aluminum Screw Cap Lining?

When selecting the appropriate lining for the 28mm aluminum screw cap, the choice largely depends on the specific product being packaged and the necessary sealing, protection, and preservation characteristics.

General guidelines for choosing a liner:

- Cost-effective solution: If budget is a concern, EPE liners offer a good balance of sealing and protection for most products.

- Tamper-evident and high-barrier performance: For products requiring secure sealing and protection, especially those sensitive to environmental factors, foil or induction-seal liners are the best choice.

- Chemical resistance and durability: For products like oils or chemicals, PET or PVC liners provide the necessary durability and barrier properties.

- Cushioning and protection during transport: When additional cushioning is needed to protect fragile items, foam liners are an ideal choice.

By understanding the needs of the product being packaged (such as sensitivity to moisture, air, or temperature), you can choose the most suitable liner to ensure optimal protection and product lifespan.

| Application Area | Recommended Liner Type | Liner Features | Suitable Products |

| Food and Beverage | EPE (Expanded Polyethylene) Liner, PVC Liner | - Lightweight and cost-effective - Provides good sealing performance - Prevents leakage and keeps products fresh | - Juices - Sauces - Edible oils - Seasonings |

| Cosmetics | EPE (Expanded Polyethylene) Liner, Foam Liner | - Non-toxic, chemically resistant - Provides sealing performance to maintain product freshness - Foam liners offer additional protection | - Perfume - Creams - Shampoos - Essential oils |

| Pharmaceuticals | PVC Liner, Aluminum Foil Liner | - Provides strong sealing - PVC liners offer good moisture resistance - Aluminum foil liners provide tamper-evident function | - Medicinal syrups - Herbal liquids - Medical liquids |

| Essential Oils or Sensitive Liquids | Aluminum Foil Liner, Induction Seal Liner | - Provides high protection, preventing oxygen and moisture infiltration - Induction seals ensure tamper-evident closure - Aluminum foil liner prevents oxidation | - Essential oils - Perfume - High-end liquids |

| Oils, Chemicals, and High-performance Liquids | PET (Polyester) Liner, Aluminum Foil Liner | - Provides good sealing - Strong chemical resistance and corrosion protection - Aluminum foil liners provide additional protection | - Industrial oils - Automotive fluids - Chemicals |

| Moisture-sensitive Products | PVC Liner, Aluminum Foil Liner | - Provides strong moisture protection - PVC liners effectively block oxygen - Aluminum foil liners provide moisture and oxidation resistance | - Pharmaceuticals - High-end food products (such as vitamins, supplements) |

- EPE liner is suitable for general food, beverages, and cosmetics, offering good sealing performance and cost-effectiveness.

- PVC liner provides higher moisture protection, suitable for products that need to be protected from oxidation and moisture, such as pharmaceuticals and certain foods.

- Aluminum foil liners and induction seal liners provide high protection and tamper-evident functionality, ideal for sensitive liquids and premium products.

- PET liners are suitable for oils, chemicals, and products requiring higher chemical resistance and sealing performance.

When choosing a 28mm aluminum screw cap, ensure compatibility with your specific bottle type and neck finish. It is recommended to conduct product testing to confirm whether the cap fits your application.

The following bottle caps may interest you

Further reading : Aluminum ROPP CapBeer Aluminum Anti-counterfeiting Bottle CapLiquor Aluminum CapWhite Aluminum Bottle CapAluminum roll-printing and milling anti-counterfeiting bottle capWine Aluminum CapROPP Aluminum Caps for WaterBeverage Bottle Aluminum CapAluminum Caps for VinegarVodka Bottle Aluminum CapsBlack Aluminum Bottle CapRum Aluminum Screw Caps 30x35mmOlive Oil Aluminum CapAluminum Cap for Whiskey Alcohol Spirit Glass Bottle31.5x24mm embossing and milling Aluminum Cap for Alcohol Whisky VodkaAluminum Bottle Cap 30x60mm for Wine and Spirits Bottles30x35mm Aluminum Bottle Cap for Spirits and Alcoholic Beverages30x43mm Wine Aluminum Cap25x43mm Aluminium Pilfer Proof Bottle Cap30x44mm Aluminum Bottle Cap for Spirits30x35mm Aluminium ROPP Cap30x60mm Hot Stamping Cover Wine Bottle Lids - Alcohol Whiskey Vodka Aluminum Bottle Cap38mm Beverage Drinks Aluminum CapBeer Aluminum Bottle CapAluminum anti-counterfeiting bottle capPull-Off Aluminum Bottle CapTamper-Evident Aluminum Bottle Cap38mm Aluminum ROPP Cap38mm Aluminum Cap26mm 42mm Ring Pull Aluminum Cap30x60mm Aluminum Vodka Tequila Caps30x60mm Aluminum ROPP Caps for Wine Glass BottlesPull Ring Easy Open Aluminum Crown Caps30×60 mm Aluminum ROPP Caps for Whiskey Glass BottlesBlue Aluminum Caps33x47mm Side Emboss Aluminum LidsAluminium Pilfer Proof Caps30 x 35 EPE tin liner ROPP Closures30x60mm Aluminum CapAluminium ROPP (18x12)18mm ROPP Aluminum Caps22mm Aluminium Ropp Caps25mm Aluminium Ropp Caps31.5 mm ROPP Aluminum Cap46 mm ROPP Aluminum Cap53 mm ROPP Aluminum CapColored ROPP Aluminum CapsPrinted ROPP Aluminum Caps33x58 Pilfer-Proof ROPP Aluminum Cap38x18mm Aluminum ROPP Cap