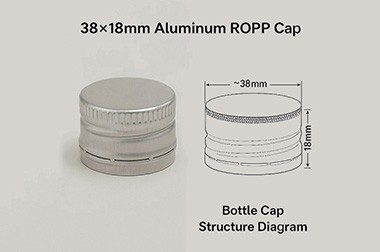

38mm Aluminum ROPP Cap

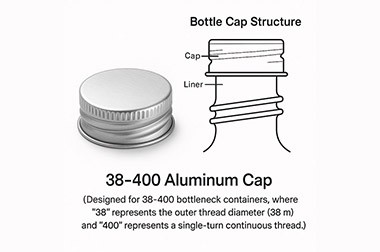

38mm ROPP (Roll On Pilfer Proof) aluminum cap is a widely used metal sealing solution for various liquid packaging applications. With its excellent sealing performance, tamper-evident functionality, and recyclability, it has become the preferred packaging component in industries such as food and beverage, pharmaceuticals and healthcare, and cosmetics.

The 38mm aluminum ROPP (Roll-On Pilfer Proof) cap is a specially designed sealing system used for securely capping bottles, especially in industries that require tamper resistance and durability. Its name derives from its manufacturing process ("roll-on") and anti-tampering function ("pilfer-proof"). Made from lightweight aluminum, this cap is widely used for packaging beverages, pharmaceuticals, and specialty liquids due to its reliability and safety.

38mm ROPP Aluminum Cap Specifications and Dimensions

| Dimension Parameter | Value | Tolerance Range | Measurement Position |

| Outer Diameter | 38mm | ±0.2mm | Maximum diameter at the top |

| Height | 16.5-18mm | ±0.15mm | Vertical distance from top to bottom |

| Thread Diameter | 37.7mm | ±0.15mm | Root diameter of the thread |

| Thread Effective Length | Approximately 12mm | ±0.5mm | Effective engagement portion of the thread |

| Tamper-Evident Band Width | Approximately 3mm | ±0.3mm | Widest part of the tamper-evident band |

| Cap Blank Diameter | 66mm | ±0.5mm | Size of the raw material blank |

The dimensional design of the 38mm ROPP aluminum cap fully considers compatibility and usability with various containers, including bottle neck matching design, ergonomic design, manufacturing process adaptability, and tamper-evident functionality.

Material and Structure of 38mm Aluminum ROPP Cap

Material of 38mm Aluminum ROPP Cap

Main Material

- 3004 Aluminum Alloy: An Al-Mn-Mg series alloy with good formability, corrosion resistance, and strength.

- 5052 Aluminum Alloy: An Al-Mg series alloy with excellent corrosion resistance and cold working properties.

Liner Materials

- PE (Polyethylene): Offers good flexibility and chemical stability.

- EVA (Ethylene-Vinyl Acetate Copolymer): Provides better elasticity and sealing performance.

- Silicone: Excellent heat resistance, cold resistance, and chemical stability.

Material Selection Recommendations for 38mm ROPP Aluminum Caps

According to different application scenarios and product characteristics, HC Aluminum recommends suitable material combinations for customers:

-

General Beverage Packaging

3004 aluminum alloy body combined with PE liner offers high cost performance and is suitable for most non-carbonated beverages and food packaging.

-

Carbonated Beverage Packaging

5052 aluminum alloy body combined with EVA liner provides better pressure resistance and sealing performance, capable of withstanding the internal pressure of carbonated drinks.

-

High-Temperature Sterilized Products

3004 aluminum alloy body combined with silicone liner can withstand high-temperature sterilization without deformation or performance degradation.

Structure of 38mm Aluminum ROPP Cap

| Component Name | Material Description | Functional Description |

| Cap Body | Aluminum (generally corrosion-resistant aluminum alloy suitable for roll-forming) | Surface includes pre-formed knurling for hand grip and easy twist-off, providing strong bottleneck protection. |

| Liner | Optional materials: PE (Polyethylene), EPE (Expanded Polyethylene), TPE, PVDC, etc. | Provides sealing function to prevent liquid leakage; liner material is selected based on liquid type (e.g., carbonated beverages, juice, pharmaceuticals) for compatibility. |

| Tamper Evidence Band | Aluminum perforated ring, connected to the lower end of the cap body | Breaks off as the cap is opened, leaving visible signs of opening, preventing unauthorized access, ensuring package integrity and consumer safety. |

| Knurled Skirt | Embossed or pre-patterned texture on the outer aluminum shell | Provides friction for twisting open/close, enhancing user experience during opening. |

| Threading | Threads formed by roll-forming on the inner wall of the aluminum shell | Matches the bottle neck threading to ensure tight fit and repeated twist sealing. |

- Skirt and tamper band: Begins as a smooth skirt with a frangible lower band (pilfer band). Upon first opening, this band breaks—providing visible tamper evidence .

- Liner assembly: Usually includes an inner liner made of elastomeric or EPE/PP materials, ensuring leak-proof sealing and content compatibility. Can be L-type (for carbonated drinks), epoxylite, or elastomer-lined depending on application .

38mm Aluminum ROPP Cap Compatibility

- Standard diameter of 38mm, suitable for glass bottles, plastic bottles, and aluminum bottles

- Can be adapted to containers with diameters ranging from 20–70mm (customized equipment required)

38mm Aluminum ROPP Cap Liner System

- Includes a liner (usually PVC, foam, or cork) to enhance sealing performance.

- Liner selection depends on the application: heat resistance (e.g., hot-filled beverages), chemical compatibility (e.g., pharmaceuticals), or gas barrier properties (e.g., carbonated beverages).

Liner materials are selected based on the contents. Common liners include:

| Liner Material | Application Field | Characteristics |

| EPE (Expanded Polyethylene) | Beverages, water | Good elasticity, reliable sealing |

| TPE / PVC liner | Spirits, condiments | Suitable for high alcohol content liquids |

| No liner / Aluminum foil seal | Disposable packaging or induction sealing | Low cost, suitable for mass production |

Difference Between 38mm and 42mm Aluminum ROPP Caps

| Comparison Dimension | 38mm ROPP Cap | 42mm ROPP Cap |

| Size and Structure | Diameter: 38mm | Larger diameter (42mm), requires wider bottleneck |

| Height: 17.0–17.7mm | Height may increase (approx. 19–20mm) to maintain sealing strength | |

| Application Scenario | Mainly used for juice, beer, functional drinks (below 500ml) | Suitable for large-volume containers (e.g., beverages over 1L, sauce bottles), requires higher pressure resistance |

| Production Process Adjustments | Rolling machine mold adapted to 38mm threading | Requires customized larger rolling molds |

| Smaller printing area | Larger printing area, may require adjustments in printing equipment precision | |

| Material and Cost | Approx. 2g aluminum per cap, lower cost | Increased aluminum usage (approx. 2.5–3g), cost rises by 10–15% |

| Sealing Performance | Fits standard PET/glass bottles (GPI-1650 neck finish) | Requires thicker liner or enhanced coating to accommodate internal pressure of larger bottles |

Application Scenarios of 38mm ROPP Aluminum Cap

Which industries commonly use the 38mm Aluminum ROPP Cap?

Widely used across various industries, including:

- Spirits, wine, beer, cider, and soft drinks.

- Edible oils, pharmaceuticals, cosmetics, agrochemicals, and lubricants.

- Contents: Juice, soft drinks, coffee, alcoholic/non-alcoholic beverages.

- Containers: Sealed glass bottles and aluminum containers.

- Customization needs: Printable logo, customizable color options such as white.

38mm Aluminum ROPP Cap Packaging for Glass Bottles

| Item | Description |

| Bottle Neck Outer Diameter | Typically 38mm (±0.2mm), requires precise measurement |

| Thread Type | Such as GPI, MCA, BVP, etc., with different pitch standards |

| Bottle Neck Height | Affects the skirt height and sealing position of the cap |

| Bottle Neck Shape | Presence of tamper-evident ring lock or chamfer, directly impacts aluminum cap design |

How to Choose the Right Size for 38mm Aluminum ROPP Cap?

ROPP caps refer not only to bottle neck diameter, but also include height, thread pitch, and other complete parameters:

| Cap Specification | Typical Application | Height (mm) | Features |

| 38×18 mm Aluminum ROPP Cap | Juice, alcoholic beverages | 18 | Commonly paired with glass bottles, moderate height |

| 38×15 mm Aluminum ROPP Cap | Pharmaceuticals, food | 15 | Shorter, lightweight design |

| 38×21 mm Aluminum ROPP Cap | High-pressure contents | 21 | Deeper skirt, stronger sealing performance |

Aluminum caps typically require a 3–5 mm allowance for the skirt fold, so the cap height should be adjusted according to the bottle neck height.

Reference Applications of 38mm Aluminum ROPP Cap

| Scenario | Glass Bottle Size | Recommended Cap |

| Beverage/Juice | 38mm MCA bottle neck | 38×18 mm aluminum cap, EPE liner |

| Spirits/Condiments | 38mm standard thread | 38×21 mm, with tamper-evident ring, PVC liner |

| Pharmaceuticals/Tinctures | 38mm short neck | 38×15 mm, TPE liner or aluminum foil liner |

Advantages of 38mm ROPP Aluminum Cap

- Tamper-evidence: Clearly indicates unauthorized access.

- Enhanced safety: ROPP design prevents tampering and provides clear evidence of unauthorized opening.

- Durability: Aluminum structure ensures the cap can withstand handling, transport, and environmental factors without performance degradation.

- Resealability: After opening, the cap can be re-tightened to maintain freshness and prevent spillage.

- Barrier sealing: Provides moisture/oxygen protection and leak resistance when properly lined.

- Compatibility: Suitable for glass or PET bottles that can withstand thread-forming pressure.

- Aesthetic appeal: Sleek metallic surface is attractive on retail shelves and enhances brand presentation.

- Product preservation: Excellent sealing helps maintain product freshness and prevent contamination.

- Customization: Available in multiple colors with options for embossing, debossing, or printed logos/text.

- Recyclability: Aluminum is 100% recyclable, supporting sustainability goals.

Production and Quality of 38mm ROPP Aluminum Cap

Manufacturing Process of 38mm Aluminum ROPP Cap

| Process Step | Description |

| Aluminum Material Selection | Uses 3-series aluminum alloy for its good ductility and corrosion resistance, suitable for stamping forming |

| Coating Treatment | Inner layer: Epoxy resin (anti-corrosion) |

| Outer layer: Polyester resin (abrasion resistance) | |

| Pre-coated slip layer (e.g., PP) to optimize capping performance | |

| Liner Preparation | Specialized equipment melts non-PVC materials (e.g., TPE/PE), forms a bead, and compresses it into the cap to form a liner |

| Sealing Adaptability | Liner must fit tightly, withstand high-temperature sterilization (e.g., pasteurization) or cold filling environments, ensuring sealing performance |

| Surface Printing | Custom branding with silk screen printing, hot stamping, UV printing, etc., for logo, anti-counterfeit mark, and graphics |

| Curing Process | Post-printing curing by hot air/UV to enhance scratch and weather resistance of printed graphics |

| Thread Forming | Cap is placed on the bottle neck, and thread structure is rolled into the cap body using rolling equipment |

| Tamper-Evident Ring Forming | Simultaneously forms the tamper-evident band which breaks upon first opening to provide evidence of tampering |

| Quality Inspection | Inspects printing quality, liner integrity, and visual defects, and verifies dimensional tolerance |

How to Ensure the Quality of 38mm Aluminum ROPP Cap?

Six Key Elements to Ensure the Quality of ROPP Caps

| Stage | Core Measures |

| Raw Material | Select high-quality aluminum, control thickness and surface finish |

| Forming Process | Use high-precision molds and automated equipment to avoid deformation and errors |

| Surface Treatment | Ensure uniform coating with strong adhesion |

| Dimensional Accuracy | Strict tolerance control to match sealing equipment requirements |

| Sealing Test | Ensure tight seal with the bottle and reliable tamper-evidence |

| Packaging & Shipment | Scratch-resistant and anti-oxidation packaging, with inspection report attached |

Selection Process of 38mm Aluminum Cap

- Confirm bottle neck diameter, thread type, and height

- Choose matching aluminum cap height

- Select liner material based on bottle contents

- Opt for tamper-evident structure and knurling process

- Check compatibility with capping equipment

The 38mm aluminum ROPP cap combines functionality, security, and environmental responsibility. Its tamper-proof design, cross-industry adaptability, and recyclable material make it the preferred choice for brands prioritizing product safety and sustainability.

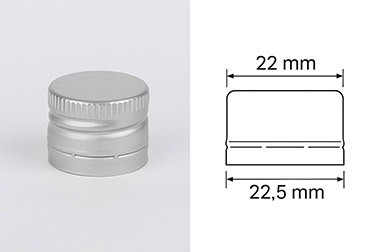

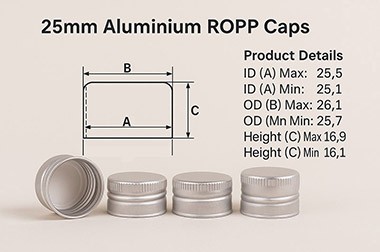

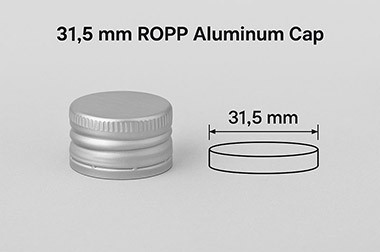

The following bottle caps may interest you

Further reading : Aluminium Screw CapsBeer Aluminum Anti-counterfeiting Bottle CapLiquor Aluminum CapWhite Aluminum Bottle CapAluminum roll-printing and milling anti-counterfeiting bottle capWine Aluminum CapBeverage Bottle Aluminum CapAluminum Caps for VinegarVodka Bottle Aluminum CapsBlack Aluminum Bottle CapRum Aluminum Screw Caps 30x35mmOlive Oil Aluminum CapAluminum Cap for Whiskey Alcohol Spirit Glass Bottle31.5x24mm embossing and milling Aluminum Cap for Alcohol Whisky VodkaAluminum Bottle Cap 30x60mm for Wine and Spirits Bottles30x35mm Aluminum Bottle Cap for Spirits and Alcoholic Beverages30x43mm Wine Aluminum Cap30x44mm Aluminum Bottle Cap for Spirits28x18mm Aluminium Closure30x60mm Hot Stamping Cover Wine Bottle Lids - Alcohol Whiskey Vodka Aluminum Bottle Cap28mm Beverage Drinks Aluminum CapBeer Aluminum Bottle CapAluminum anti-counterfeiting bottle capPull-Off Aluminum Bottle Cap28mm Aluminium Screw Cap28mm Aluminum Cap28x18mm aluminum bottle cap for VodkaScrew Cap 28-400 Aluminum Gold With PE Liner28mm 28-400 Aluminum Metal Cap with Pulp & Poly Liner28mm/410 Aluminium Cap with EPE Liner26mm 42mm Ring Pull Aluminum Cap30x60mm Aluminum Vodka Tequila CapsPull Ring Easy Open Aluminum Crown Caps250 ml Bottles 28×15 mm MCA Aluminum CapsBlue Aluminum Caps28/400 GPI Top Embossed Aluminum-plastic Screw Cap33x47mm Side Emboss Aluminum Lids24mm Aluminium Screw Cap28mm Black Aluminum Screw Top Cap28mm (R3) Aluminium Screw Cap18mm Aluminium Screw Cap30x60mm Aluminum CapAluminum Screw Caps for Wine And Spirits53-400 Aluminum Screw Cap With Customizable Liner Options18-400 Black Aluminum Screw Top Caps30x60 Screw Cap Aluminum Closure18-410 Silver Aluminum Screw Top CapPre-threaded Aluminium Screw Caps20-400 Black Aluminum Screw Top Caps24-400 Aluminum Screw Cap With Customizable Liner Options20-410 Silver Aluminum Bottle Cap24-410 Aluminum Cap30x44mm Aluminum Screw Cap