Aluminum ROPP Cap

Aluminum ROPP (Roll-On Pilfer-Proof) caps are widely used closures designed to provide tamper-evident sealing, ensuring product integrity and consumer safety.

Aluminum ROPP caps consist of a thin layer of aluminum shell. During the sealing process, the cap is placed over the bottle neck, and a set of rollers applies pressure to form threads on the cap, which then engage with the corresponding threads on the bottle neck. This rolling action creates a secure tamper-evident seal. By combining the ductility of aluminum with precision roll-forming technology, the core value of aluminum ROPP caps lies in their tamper-resistance and sealing reliability.

Aluminum ROPP caps (Roll-on Pilfer-proof Caps) are widely used as metal closures in food and beverage packaging. Made from high-quality aluminum alloy materials, these caps form threads on the bottle mouth through a special process to achieve a tight seal. ROPP caps feature a unique tamper-evident design that leaves visible damage marks upon first opening, ensuring product safety and integrity.

With their excellent physical properties and processing characteristics, aluminum ROPP caps have become the ideal choice for packaging alcoholic beverages, soft drinks, mineral water, health supplements, and other liquid food products. In addition to providing reliable sealing performance, they also enhance product visual appeal through refined printing and surface treatments, serving as a key element in brand differentiation.

HC Bottle Cap Manufacturing Co., Ltd. has over 17 years of experience in providing different kinds of aluminum caps, plastic caps, aluminum-plastic caps, glass bottles, and other packaging products. Our products are exported to more than 20 countries around the world, including the United States, Europe, South Africa, Southeast Asia, etc.

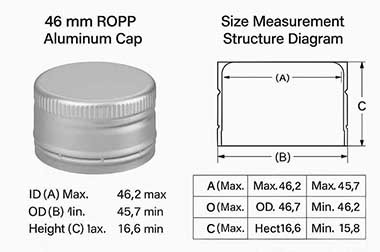

Aluminum ROPP Cap Sizes and Specifications

Aluminum ROPP caps are available in various sizes, with diameters ranging from 25mm to 38mm and heights up to 60mm. For non-refillable caps, the size options typically range from 28mm to 32.5mm.

Each size is available with a suitable sealing effect based on different product types, ensuring the container's seal and tamper-proof functionality.

HC Bottle Cap Manufacturing Co., Ltd. is equipped with internationally leading roller printing and capping equipment, as well as production lines for commonly used 28mm and 38mm caps. Our best-selling products include aluminum anti-counterfeit caps and composite anti-counterfeit caps, which are exported to international markets such as Asia, Europe, and the Americas.

Aluminum ROPP Cap Quality Testing

The quality testing of aluminum ROPP caps covers multiple indicators such as appearance, dimensions, sealing performance, and pressure resistance. Each item is designed to ensure the comprehensiveness of quality.

At HC Bottle Cap Manufacturing Co., Ltd., we are committed to producing high-quality aluminum ROPP caps. All aluminum ROPP caps undergo strict quality inspection processes.

| Testing Items | Description |

| Raw Material Inspection | We rigorously select high-quality aluminum materials to ensure they meet international standards, ensuring the durability and sealing performance of the caps. |

| Dimensional Accuracy Testing | Using advanced measuring equipment, we accurately measure the diameter, height, and thread specifications of the caps to ensure perfect compatibility with the bottle neck. |

| Sealing Performance Test | We simulate actual use conditions to test the sealing performance of the caps, ensuring that the product will not leak during transport and storage. |

| Corrosion Resistance Evaluation | We conduct salt spray tests to evaluate the corrosion resistance of the caps, ensuring the stability of the product in various environments. |

| Mechanical Strength Test | We perform tensile and compression tests to evaluate the mechanical strength of the caps, ensuring their reliability during use. |

| Appearance Quality Inspection | We visually inspect the surface of the caps to ensure they are free of scratches, dents, or other defects, meeting aesthetic requirements. |

Aluminum ROPP Cap Hot-Selling Product Series

| Product | Image | Description |

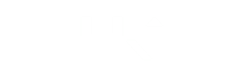

| 28mm ROPP Cap |

|

The 28mm ROPP Cap is a common sealing cap, suitable for various beverage packaging, especially for mineral water, beer, soft drinks, and energy drinks. This cap provides excellent sealing, ensuring the product's original flavor and safety, and also offers tamper-proof functionality. It is widely used in bottled beverages on the market. |

| 38mm ROPP Cap |

|

The 38mm ROPP Cap is designed for bottles with larger openings and is suitable for bottled water, beer, wine, and other beverages. Its larger size ensures excellent sealing and tamper-proof properties, and it can accommodate larger capacity bottled products. It is commonly used for premium beverages and large bottle packaging. |

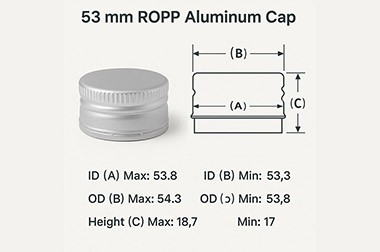

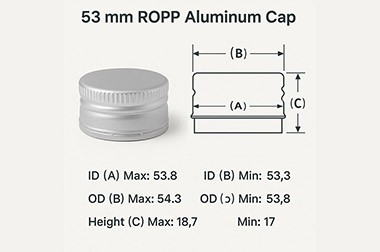

| 53mm ROPP Cap |

|

The 53mm ROPP Cap is suitable for special bottled beverages, such as certain spirits or large bottled drinks. Its size provides strong sealing for larger bottle openings, preventing leaks and ensuring product safety. Additionally, the tamper-proof feature enhances brand protection. |

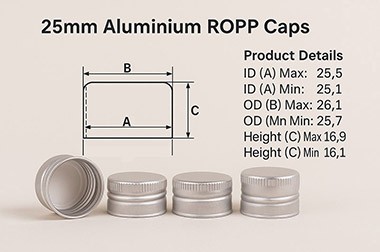

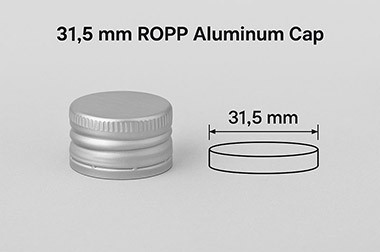

| 31.5mm ROPP Cap |

|

The 31.5mm ROPP Cap is an ideal choice for standard beverage bottles, widely used for water, beer, soft drinks, and other everyday beverages. Its standard size fits a variety of bottle types, ensuring a good seal and is commonly seen in bottled beverages in the market. It is a typical sealing cap for consumer daily-use products. |

| Printed ROPP Cap |

|

Printed ROPP Caps not only provide basic sealing protection but also allow for brand visual display on the bottle. Through printed patterns, brands can increase their visibility in the market, especially for beverages, seasonings, and alcoholic products. These caps offer both functionality and aesthetic appeal. |

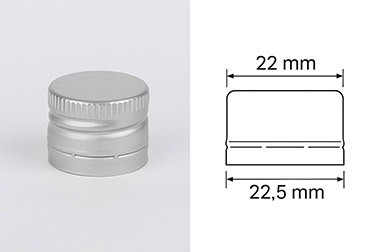

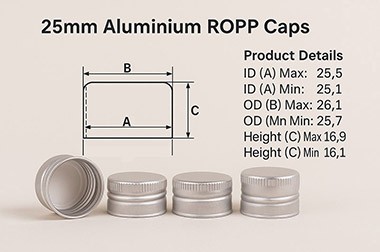

| 25mm ROPP Cap |

|

The 25mm ROPP Cap is suitable for small bottle products, such as small beverage bottles and seasoning bottles. Its compact size is ideal for lightweight beverage packaging, providing reliable sealing. It is commonly used in bottled mineral water, juice, and other small packaging food and beverage products. |

| 28x15.5 mm Aluminum ROPP Cap |

|

The 28x15.5 mm Aluminum ROPP Cap is suitable for bottled products like mineral water, beer, soft drinks, and energy drinks. This cap, with its precise size and tight sealing performance, effectively preserves the freshness and original taste of the liquid inside the bottle. It also features tamper-proof functionality and is commonly used in everyday consumer bottled packaging. |

| 28x18 mm Aluminum ROPP Cap |

|

The 28x18 mm Aluminum ROPP Cap is suitable for packaging a wide range of beverages such as water, beer, soft drinks, and wine. It provides excellent sealing performance, ensuring the safety and freshness of beverages during transportation and storage, while also featuring tamper-proof labeling. It is widely used for medium-sized bottled drinks. |

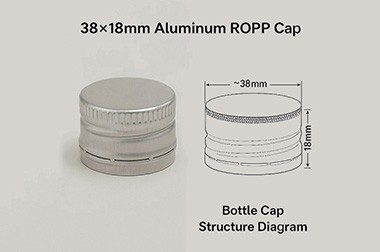

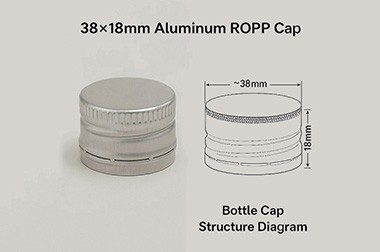

| 38x18 mm Aluminum ROPP Cap |

|

The 38x18 mm Aluminum ROPP Cap is designed for larger bottle openings and is ideal for sealing large bottled beverages such as bottled water, beer, and wine. Its larger size not only ensures a perfect seal but also enhances tamper-proof properties, making it suitable for premium beverage packaging. |

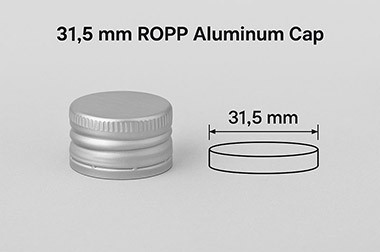

| 31.5x18 mm Aluminum ROPP Cap |

|

The 31.5x18 mm Aluminum ROPP Cap is an ideal choice for standard beverage bottles, widely used for water, beer, soft drinks, and other common beverages. This cap fits a variety of standard bottle types, providing reliable sealing and also featuring a tamper-proof design. It is commonly found in various bottled beverages on the market. |

Aluminum ROPP Cap Features

Excellent Performance

-

Tamper-Evident Function

ROPP caps utilize advanced roll-on technology to form a unique sealing structure during application, which cannot be resealed once opened.

-

Sealing Performance

Aluminum ROPP caps provide excellent sealing performance, effectively preventing leakage and blocking external gases, moisture, and contaminants, thereby extending product shelf life.

-

High Compatibility

Aluminum ROPP caps are highly adaptable and suitable for various types of bottles, such as glass bottles, PET bottles, and aluminum bottles. Whether for traditional glass-bottled beverages or modern lightweight PET packaging, ROPP caps deliver perfect sealing performance.

-

High Strength and Lightweight

Aluminum ROPP caps are made from high-quality aluminum alloys (such as 3105, 8011, etc.), offering the dual advantages of high strength and light weight.

-

Good Temperature Resistance

Aluminum ROPP caps maintain stable performance across a wide temperature range and can withstand high-temperature sterilization processes without deformation or damage. After sterilization, both the internal and external coatings should remain intact, without discoloration, peeling, or water stains.

-

Highly User-Friendly and Eco-Friendly

The twist-off design requires no tools—consumers can easily open and reclose the cap, supporting multiple uses. Aluminum is infinitely recyclable, making it convenient for container recycling and reuse.

Safety and Hygiene Assurance

The materials and production processes of aluminum ROPP caps strictly comply with international food safety standards, including FDA, EU regulations on food contact materials, and China’s GB 4806.9-2023. Aluminum is a non-toxic, odorless metal that does not release harmful substances or affect product flavor. It naturally forms a dense oxide layer in air, giving it strong corrosion resistance.

Advantages in Material Sustainability

-

95%

Aluminum recycling rate

-

5%

Energy required to recycle aluminium

-

100%

Recyclable

Aluminum is a highly recyclable material. Aluminum ROPP caps can be 100% recycled and reused without loss of performance. Compared to plastic caps, aluminum ROPP caps require significantly less energy during the recycling process and can be infinitely reused, aligning with modern sustainability requirements.

Aluminum ROPP Cap Liners

Caps can be equipped with different liner materials according to needs, such as foam liners and EPE (expanded polyethylene) liners, which help enhance sealing and prevent leakage.

- Foam: Provides basic sealing performance, suitable for general beverages and foods.

- EPE (Expanded Polyethylene): Offers better softness and leak resistance, suitable for high-value liquid products such as wine, spirits, etc.

Aluminum ROPP Cap Surface Treatments

-

Diverse Appearance and Custom Designs

Printing and surface treatments: The surface of aluminum ROPP caps can undergo a variety of printing and finishing techniques, including offset printing, embossing, hot stamping, matte or glossy coatings, and more.

-

Color and Decorative Options

Aluminum ROPP caps can be customized in various colors and patterns according to branding needs, meeting the demands of different product positioning and market segmentation.

-

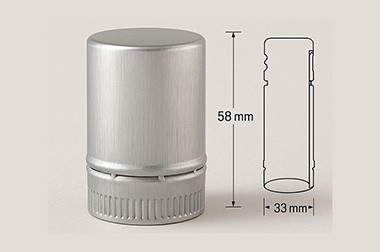

Customized Shapes and Sizes

Aluminum ROPP caps can be tailored to fit various bottle mouth sizes and product characteristics, ranging from as small as 20mm to over 60mm, fulfilling diverse packaging requirements.

| Surface Treatment | Image | Description |

| Printed ROPP Cap |

|

Through customized printing technology, brand logos, text, or other designs can be printed on the surface of the cap. This treatment method helps increase brand exposure, improve market recognition, and ensures that the printed design does not fade over time, maintaining a lasting visual effect. |

| Colored ROPP Cap |

|

A variety of color options are available, such as black, blue, gold, red, silver, white, and yellow. Colored caps can attract consumer attention, enhance product recognition, and different colors can convey different brand images and product positioning. |

| Aluminum Embossed Anti-Counterfeit Cap |

|

Using embossing technology, unique anti-counterfeit marks are created on the surface of the cap to prevent counterfeiting. This surface treatment provides additional security protection for high-end products, especially for markets requiring high anti-counterfeit standards, such as alcoholic beverages and pharmaceuticals. The anti-counterfeit effect enhances consumer trust in the brand. |

Aluminum ROPP Cap Applications

| Application | Image | Description |

| Bottled Mineral Water and Natural Water |

|

Aluminum ROPP Cap is widely used in bottled mineral and natural water to ensure that the water source remains free from external contamination. The cap provides excellent sealing performance, effectively maintaining the water's cleanliness and freshness, preventing air, dust, or other contaminants from entering the bottle, ensuring the safety of the water quality and consumer health. |

| Drink Bottles Ropp Aluminum Cap |

|

For drink bottles, such as carbonated drinks and juices, the Aluminum ROPP Cap provides sealing protection to prevent the drink from being contaminated or leaking due to external factors. Its superior sealing performance helps the beverage maintain freshness for an extended period, ensuring stable taste and quality. |

| Wine and Red Wine Bottles Ropp Aluminum Cap |

|

In wine and red wine bottles, the Aluminum ROPP Cap effectively prevents air from entering the bottle, preserving the quality and flavor of the wine. It can extend the shelf life of the wine, prevent oxidation, and provide comprehensive protection for the delicate taste and quality of the wine. |

| Cooking Oil Bottles Ropp Aluminum Cap |

|

In cooking oil bottles, the Aluminum ROPP Cap features excellent tamper-evident functionality, ensuring the purity of the oil. The cap effectively prevents the oil from being exposed to air, reducing contamination, and preventing unauthorized opening of the container, ensuring that the product purchased by consumers meets quality standards. |

| Spirits and Wine Bottles Ropp Aluminum Cap |

|

For spirits and premium wine bottles, the Aluminum ROPP Cap not only provides tamper-evident functionality but also features anti-counterfeit properties. Through unique design and materials, it ensures the bottle has not been tampered with, providing professional security protection for high-end beverages and enhancing the brand's reputation. |

| Vinegar Bottles Ropp Aluminum Cap |

|

The Aluminum ROPP Cap is also suitable for vinegar bottles, ensuring that the liquid inside the bottle remains untampered with, preserving the purity of the vinegar. Its strong sealing properties effectively prevent the vinegar from coming into contact with external air, reducing the loss of volatile components and maintaining the product's quality and freshness. |

| Other Liquid Containers Ropp Aluminum Cap |

|

Aluminum ROPP Cap is widely used in other liquid containers such as olive oil bottles, vodka bottles, rum bottles, etc. These caps provide ideal sealing protection for various liquids and prevent the bottle from being tampered with, ensuring the quality and safety of the product contents. |

Beverage Sector:

Mineral Water / Soft Drinks: 28×18mm tamper-evident screw water cap

Wine / Spirits: 30×60mm custom aluminum cap (wine), 31.5×24mm olive oil cap (for spirit bottles)

Beer: Compatible with standard crown cap sizes, sealing performance meets carbonated pressure requirements

Pharmaceuticals / Cosmetics: Complies with packaging standards for oxygen and moisture barrier, ensuring product stability

High-Precision Manufacturing of Aluminum ROPP Caps Ensures Superior Quality

Advanced Production Process

- Raw Material Preparation: The production of aluminum ROPP caps begins with the selection of high-quality aluminum alloy coils, commonly using alloys such as 8011 H14 and 3003 H16. Thickness typically ranges from 0.20mm to 0.23mm, and width from 449mm to 796mm. These materials must pass strict inspections to ensure flat surfaces free from rolling marks, scratches, and stains, guaranteeing quality in subsequent processing.

- Printing and Coating: The aluminum coils undergo surface pretreatment, followed by printing and coating based on design requirements. Printing is usually carried out on high-speed rotary presses capable of printing around 100 caps per minute. After printing, the coils go through a drying process. The coating not only adds decorative effect but also enhances corrosion and wear resistance, ensuring a good appearance under various conditions.

- Stamping and Forming: Printed and coated aluminum coils are fed into stamping machines to produce cap blanks according to preset dimensions. The stamping process requires high-precision molds and equipment to ensure accurate dimensions and clean edges. To maintain cutting quality, blades used in stamping machines are typically made of high-carbon steel, capable of cutting millions of caps while remaining sharp.

- Post-processing and Assembly: The stamped cap blanks undergo further processing, including trimming, curling, and embossing, to form the final ROPP cap shape. For caps requiring liners, sealing pads are inserted or sealing material is injected during this stage. The entire production process is highly automated to ensure consistency and stability in product quality.

Precision Manufacturing Technology

- Cold Working Process: The production of aluminum ROPP caps extensively uses cold working techniques, including cold rolling, foil rolling, and annealing. These processes impart excellent ductility and strength to the aluminum, meeting the requirements of deep drawing and complex forming in ROPP caps. Processing needs vary by application—for example, wine bottle caps demand better stretchability than pharmaceutical caps, leading to differences in the annealing process.

- Roll-On Forming Technology: The threads of ROPP caps are formed using roll-on forming technology. This process requires a specialized ROPP capping machine that presses the cap onto the bottle mouth while special rollers emboss the threads onto the aluminum cap. This ensures a perfect match with the bottle threads and guarantees good sealing and ease of opening.

Strict Quality Control System

- Raw Material Quality Control: Strict quality control begins with the raw materials used in aluminum ROPP cap production. Key properties such as strength, elongation, and dimensional tolerance are thoroughly tested. Only materials that meet the standards are allowed into the production process to ensure final product quality.

- In-Process Quality Monitoring: During production, sensors and inspection devices are installed at key stages to monitor product dimensions, shapes, and print quality in real time.

- Finished Product Testing Standards: Finished aluminum ROPP caps must pass a series of rigorous tests, including sealing performance, torque opening force, temperature resistance, and alcohol resistance. For instance, caps intended for sterilization must retain intact coatings without discoloration, peeling, or water stains after testing. Microbial limit testing is also required to ensure bacterial and mold counts meet relevant standards.

- Compliance with International Standards: The production and quality control of aluminum ROPP caps strictly follow international standards, such as ISO 9001 Quality Management System and ISO 22000 Food Safety Management System.

Market Advantages and Competitive Analysis of Aluminum ROPP Caps

Multi-Sector Application and Product Compatibility

-

Beverage Industry

Widely used in carbonated drinks, mineral water, juice, tea drinks, energy drinks, and beer. Designs are tailored to suit different beverage types.

-

Alcoholic Packaging

The ideal choice for premium wine, spirits, and craft beer. Offers excellent sealing and attractive appearance to enhance product appeal.

-

Food and Health Products

Used for condiments, sauces, honey, oral liquids, and health supplements. Caps must offer strong sealing, corrosion resistance, and hygienic properties.

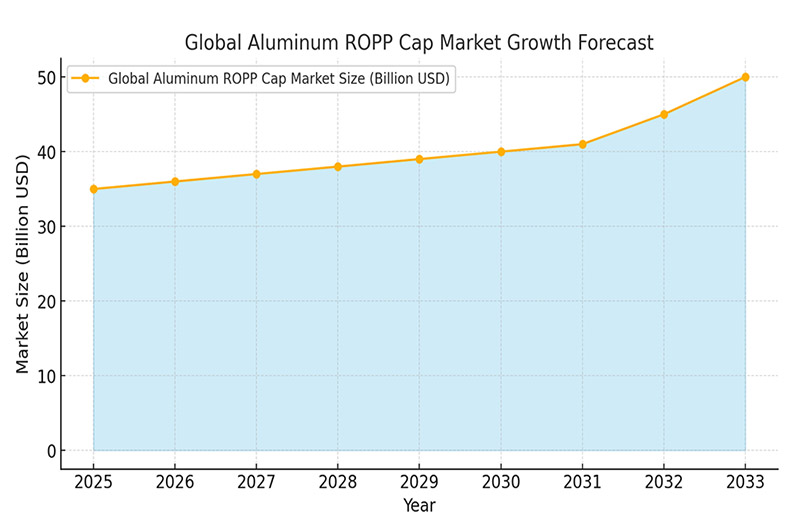

Market Advantages and Competitive Analysis

Compared to plastic caps, aluminum ROPP caps offer significant performance advantages, including superior barrier properties, better temperature and chemical resistance, and more reliable sealing. Although the initial cost of aluminum ROPP caps may be higher than some plastic caps, from a full lifecycle perspective, aluminum ROPP caps are more cost-effective. Aluminum has high recycling value, low energy requirements for recycling, and long-term use can reduce overall costs.

Reference Content:

Aluminum ROPP Closures Market Size, Share & Growth Report, 2033 https://www.valuemarketresearch.com/report/aluminum-ropp-closures-market

Aluminum Caps for Packaging Market Size, Growth & Report 2034 https://www.marketresearchfuture.com/reports/aluminum-caps-for-packaging-market-29236

The Value and Significance of Choosing Aluminum ROPP Caps

As a premium choice for food and beverage packaging, aluminum ROPP caps offer comprehensive packaging solutions for brands through their outstanding material properties, innovative design features, precise manufacturing processes, and broad market adaptability. They not only ensure product safety and quality but also enhance visual appeal and brand image, while meeting modern consumers’ expectations for sustainability.

In today’s era of increasing environmental awareness, the sustainability advantages of aluminum ROPP caps are especially important. Aluminum's high recyclability, lightweight nature, and low environmental impact make it an ideal alternative to plastic packaging, aligning with global efforts to reduce plastic pollution and promote a circular economy.

For food and beverage manufacturers, choosing aluminum ROPP caps is not only an investment in product quality and brand image, but also a commitment to environmental protection and sustainable development.

The following bottle caps may interest you

Further reading : Aluminium Screw CapsBeer Aluminum Anti-counterfeiting Bottle CapLiquor Aluminum CapWhite Aluminum Bottle CapAluminum roll-printing and milling anti-counterfeiting bottle capWine Aluminum CapBeverage Bottle Aluminum CapAluminum Caps for VinegarVodka Bottle Aluminum CapsBlack Aluminum Bottle CapRum Aluminum Screw Caps 30x35mmOlive Oil Aluminum CapAluminum Cap for Whiskey Alcohol Spirit Glass Bottle31.5x24mm embossing and milling Aluminum Cap for Alcohol Whisky VodkaAluminum Bottle Cap 30x60mm for Wine and Spirits Bottles30x35mm Aluminum Bottle Cap for Spirits and Alcoholic Beverages30x43mm Wine Aluminum Cap30x44mm Aluminum Bottle Cap for Spirits28x18mm Aluminium Closure30x60mm Hot Stamping Cover Wine Bottle Lids - Alcohol Whiskey Vodka Aluminum Bottle Cap28mm Beverage Drinks Aluminum Cap38mm Beverage Drinks Aluminum CapBeer Aluminum Bottle CapAluminum anti-counterfeiting bottle capPull-Off Aluminum Bottle Cap28mm Aluminium Screw Cap38mm Aluminium Screw Cap28mm Aluminum Cap28x18mm aluminum bottle cap for Vodka38mm Aluminum CapScrew Cap 28-400 Aluminum Gold With PE Liner28mm 28-400 Aluminum Metal Cap with Pulp & Poly Liner28mm/410 Aluminium Cap with EPE Liner26mm 42mm Ring Pull Aluminum Cap30x60mm Aluminum Vodka Tequila CapsPull Ring Easy Open Aluminum Crown Caps250 ml Bottles 28×15 mm MCA Aluminum CapsBlue Aluminum Caps28/400 GPI Top Embossed Aluminum-plastic Screw Cap33x47mm Side Emboss Aluminum Lids24mm Aluminium Screw Cap28mm Black Aluminum Screw Top Cap28mm (R3) Aluminium Screw Cap18mm Aluminium Screw Cap30x60mm Aluminum CapAluminum Screw Caps for Wine And Spirits53-400 Aluminum Screw Cap With Customizable Liner Options18-400 Black Aluminum Screw Top Caps30x60 Screw Cap Aluminum Closure18-410 Silver Aluminum Screw Top CapPre-threaded Aluminium Screw Caps20-400 Black Aluminum Screw Top Caps24-400 Aluminum Screw Cap With Customizable Liner Options38-400 Aluminum Cap20-410 Silver Aluminum Bottle Cap24-410 Aluminum Cap30x44mm Aluminum Screw Cap