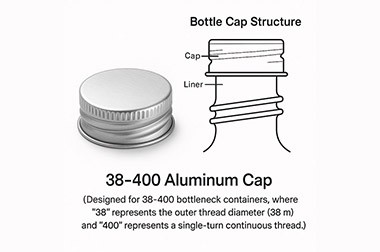

24-410 Aluminum Cap

Neck Specification 24-410: Standard Continuous Thread (Diameter 24 mm, Pitch 410)

The 24-410 Aluminum Cap is one of the most widely used metal closures in the packaging fields of beverages, food, and pharmaceuticals. Its core lies in the 24mm neck finish diameter and 410 thread pitch. As a manufacturer, HC Aluminum is committed to delivering high-quality products that meet or exceed industry standards. Through precision molds, strict production control, and comprehensive inspection, we ensure every cap offers reliable sealing, clear tamper-evidence, excellent compatibility, and an attractive appearance, meeting the demands of high-speed filling lines while providing effective protection and enhanced brand value for end products.

- "24": Refers to the outer diameter (OD) of the bottle neck designed to match the aluminum cap, which is 24 mm. This is one of the key dimensions that determines the inner diameter of the cap.

- "410": Indicates that the thread pitch of the aluminum cap is 410 mm. Thread pitch refers to the axial distance between two adjacent crests on the thread.

"Standard Continuous Thread": This refers to the type of thread.

- Continuous Thread: A continuous, uninterrupted helical thread that engages with the corresponding external thread on the bottle neck. This is the most common and universal thread type, offering smooth engagement and reliable sealing, suitable for high-speed filling lines.

- Standard: Indicates that the thread profile conforms to widely accepted industry standards, ensuring compatibility and interchangeability with 24-410 bottle necks that meet the same standard.

-

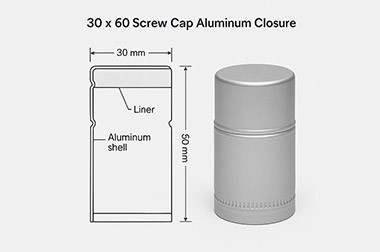

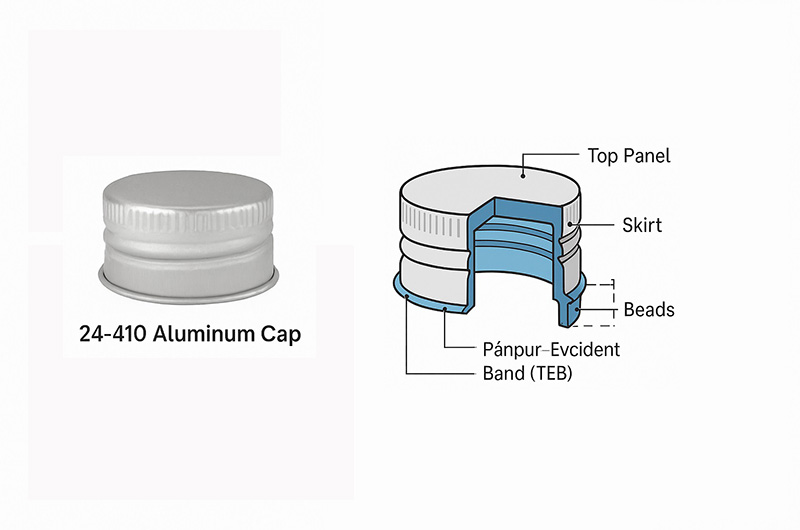

24-410 Aluminum Cap Product Structure and Components

Material: The body is made of high-quality aluminum (commonly used alloys include 3003-H19 or 3105-H19), typically with a thickness ranging from 0.18mm to 0.25mm, depending on sealing requirements, tamper-evident band design, and customer needs. Aluminum offers excellent ductility, lightweight properties, barrier performance (light and gas), and recyclability.

24-410 Aluminum Cap Structural Components

| Structural Component | Description |

| Top Panel | The flat top surface of the cap. Provides structural support and is suitable for printing, hot stamping, or other surface finishes. |

| Skirt | The cylindrical portion that extends vertically downward from the edge of the top panel. Its length affects the overall height and tightening performance of the cap. |

| Threads | Continuous internal threads formed by rolling or pressing on the inner side of the skirt, engaging with the external threads of the bottle neck. Thread shapes (e.g., C thread, E thread) and the number of turns are designed according to standards and requirements to ensure appropriate opening torque and reliable sealing. |

| Tamper-Evident Band (TEB) | A ring-shaped structure connected to the bottom of the skirt via score lines. When the cap is first opened, the score line breaks, and the tamper-evident band detaches and remains on the neck of the bottle, providing clear evidence of first opening. |

| Beads | Located on the inner side of the tamper-evident band, designed to latch into the tamper-proof groove on the bottle neck, ensuring the band does not rotate with the cap after opening, enhancing tamper-resistance. |

24-410 Aluminum Cap Liners

- Liner: A key sealing element pressed onto the inside of the top panel. Available in various materials:

- Flow-In Liner: Liquid sealing materials (such as PVC, PE, PP emulsions) are injected into the top panel and cured to form a liner.

- Composite Liner (Pulpboard/Paper/Foil Laminate): Made by laminating and compressing multiple layers of materials such as pulpboard, foil, and plastic films.

- Foam Liner: For example, PE foam gaskets.

- Induction Liner: Includes an aluminum foil layer that melts under electromagnetic induction to form a strong seal on the bottle mouth.

Key Manufacturing Processes for 24-410 Aluminum Caps

Stamping: Aluminum coils are processed through precision progressive stamping dies in multiple stages (blanking, drawing, pre-curling, etc.) to form the basic cap shape.

Thread Forming: Thread rollers are used to precisely roll continuous internal threads on the inside of the skirt.

Score Line Processing: Precision scoring lines are machined at the bottom of the skirt to form the tamper-evident band.

Curling: The edge at the bottom of the skirt is curled into shape.

Liner Application:

Flow-In: Sealing materials are injected and cured by heating.

Composite Liner: Gaskets are punched out and pressed into the cap top.

Assembly (if applicable): For certain specially designed tamper-evident bands (e.g., with beads), additional assembly steps may be involved.

Quality Inspection: Performed throughout the entire production process, including dimensions, thread fit, score line strength, sealing performance, and appearance.

Key Features and Advantages of 24-410 Aluminum Cap

- Excellent Sealing: The liner tightly bonds to the bottle finish, and the pressure generated by the threaded closure creates a reliable seal, effectively protecting contents (against leakage, moisture, oxidation, odor ingress/loss).

- Obvious Tamper Evidence: The tamper-evident band design ensures consumers can easily identify whether the product has been previously opened, enhancing product safety and brand trust.

- Outstanding Compatibility: Compliant with the 24-410 standard, it perfectly matches a wide range of bottles (glass or plastic) available in the market that conform to the same standard, facilitating customer procurement and filling.

- Suitable for High-Speed Filling: The continuous thread design makes it very suitable for capping operations on high-speed filling lines, with high efficiency.

- Lightweight and Economical: Aluminum is lightweight, and aluminum caps are typically thinner than plastic caps, reducing transportation costs. The cost of aluminum is relatively stable, making large-scale production cost-effective.

- Excellent Barrier Properties: Aluminum inherently offers great protection against light, oxygen, and water vapor, extending product shelf life.

- Good Printability: The smooth, flat surface of aluminum caps makes them ideal for high-quality brand printing (hot stamping, screen printing, offset printing, etc.), enhancing product image.

- Sustainability and Environmental Friendliness: Aluminum is infinitely recyclable, with a very high recycling rate, aligning with modern environmental trends and brand ESG goals.

24-410 Aluminum Cap Applications

- Beverages: Mineral water, purified water, carbonated drinks, juice, functional beverages, tea drinks, etc.

- Food: Edible oil, condiments (soy sauce, vinegar), sauces, syrup, honey, jam, etc.

- Pharmaceuticals: Oral liquids, syrups, some topical solutions (requires liner material to comply with pharmaceutical contact standards).

- Personal Care / Daily Chemicals: Some skincare products, hand sanitizers, cleaners, etc.

- Chemicals: Certain small-dose chemicals and reagents.

HC Aluminum 24-410 Aluminum Cap Quality Control

- Dimensional Accuracy: Inner diameter, thread dimensions (pitch, thread profile, engagement height), knurl line position/depth, tamper-evident ring inner diameter / tamper-lock size must strictly conform to standards.

- Thread Fit: Torque for opening/closing must be within standard range (usually includes minimum tightening torque and maximum opening torque) to ensure reliable sealing and ease of opening.

- Sealing Performance: Ensure reliable sealing through vacuum test, pressure test, torque retention test, etc.

- Tamper-Evident Ring Performance: Knurl line breaking force must be moderate (too tight makes it hard to break, too loose causes detachment easily); the tamper-evident ring must effectively latch onto the bottle neck's tamper-evident groove.

- Liner Integrity: No damage or detachment; material must comply with food safety or specific application requirements.

- Appearance Quality: No scratches, dents, oil stains, printing defects, etc.

The following bottle caps may interest you

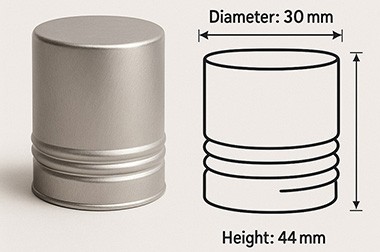

Further reading : Aluminum ROPP CapBeer Aluminum Anti-counterfeiting Bottle CapLiquor Aluminum CapWhite Aluminum Bottle CapAluminum roll-printing and milling anti-counterfeiting bottle capWine Aluminum CapROPP Aluminum Caps for WaterBeverage Bottle Aluminum CapAluminum Caps for VinegarVodka Bottle Aluminum CapsBlack Aluminum Bottle CapRum Aluminum Screw Caps 30x35mmOlive Oil Aluminum CapAluminum Cap for Whiskey Alcohol Spirit Glass Bottle31.5x24mm embossing and milling Aluminum Cap for Alcohol Whisky VodkaAluminum Bottle Cap 30x60mm for Wine and Spirits Bottles30x35mm Aluminum Bottle Cap for Spirits and Alcoholic Beverages30x43mm Wine Aluminum Cap25x43mm Aluminium Pilfer Proof Bottle Cap30x44mm Aluminum Bottle Cap for Spirits28x18mm Aluminium Closure30x35mm Aluminium ROPP Cap30x60mm Hot Stamping Cover Wine Bottle Lids - Alcohol Whiskey Vodka Aluminum Bottle Cap28mm Beverage Drinks Aluminum Cap38mm Beverage Drinks Aluminum CapBeer Aluminum Bottle CapAluminum anti-counterfeiting bottle capPull-Off Aluminum Bottle CapTamper-Evident Aluminum Bottle Cap28mm Aluminum ROPP Cap28mm Aluminum Cap28x18mm aluminum bottle cap for Vodka28x18mm Aluminium Ropp Cap38mm Aluminum ROPP Cap38mm Aluminum Cap28mm Black Aluminium ROPP Tamper Evident Screw Cap with EPE Liner28mm Silver Aluminium ROPP Cap with Liner28mm 28-400 Aluminum Metal Cap with Pulp & Poly Liner28mm/410 Aluminium Cap with EPE Liner28x15mm Aluminium ROPP Cap26mm 42mm Ring Pull Aluminum Cap30x60mm Aluminum Vodka Tequila Caps30x60mm Aluminum ROPP Caps for Wine Glass BottlesPull Ring Easy Open Aluminum Crown Caps30×60 mm Aluminum ROPP Caps for Whiskey Glass Bottles250 ml Bottles 28×15 mm MCA Aluminum CapsBlue Aluminum Caps33x47mm Side Emboss Aluminum LidsAluminium Pilfer Proof Caps28mm Black Aluminum Screw Top Cap30 x 35 EPE tin liner ROPP Closures30x60mm Aluminum CapAluminium ROPP (18x12)18mm ROPP Aluminum Caps22mm Aluminium Ropp Caps25mm Aluminium Ropp Caps31.5 mm ROPP Aluminum Cap46 mm ROPP Aluminum Cap53 mm ROPP Aluminum CapColored ROPP Aluminum CapsPrinted ROPP Aluminum Caps33x58 Pilfer-Proof ROPP Aluminum Cap38x18mm Aluminum ROPP CapRed 28mm ROPP Aluminum ClosureBrushed aluminium screw caps