22-400 Aluminum Cap

The 22-400 aluminum cap is a commonly used threaded aluminum bottle cap, primarily used for sealing various glass bottles. The "22-400 aluminum cap" typically refers to a specific size and type of aluminum cap used for various packaging purposes. "22" refers to the outer diameter of the cap (22mm), while "400" indicates the surface treatment and thread type.

-

Material:

Aluminum, lightweight, corrosion-resistant, and easy to recycle, making it a popular choice for packaging.

-

Surface Treatment:

The 400 series is a common surface treatment for aluminum caps, offering a smooth or glossy appearance. The thread type ensures that the aluminum cap securely closes the container, forming a tight seal to preserve the contents.

-

Common Applications:

The 22-400 aluminum cap is used in various applications, including pharmaceutical bottles, cosmetic packaging, food and beverage products, and more.

22-400 Aluminum Cap Specifications

22-400 Aluminum Cap Size Specifications

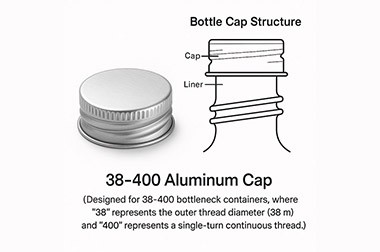

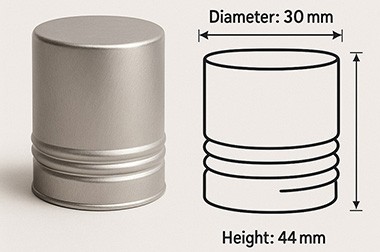

- Model: 22-400

- Material: Aluminum alloy (typically 3000 or 8000 series aluminum alloy)

- Diameter: 22mm (outer diameter)

- Height: Approximately 6-8mm (depending on specific design)

- Thread Specification: 400 (indicating specific thread type and size)

- Wall Thickness: Approximately 0.2±0.01mm

22-400 Aluminum Cap Material Specifications

The main material parameters of the 22-400 aluminum cap are:

-

Base Material: Made from 8011-H16 double-coated aluminum strip, offering good strength and corrosion resistance.

-

Weight: Approximately 0.002 pounds (about 0.9 grams).

-

Liner Material: Multiple liner options available, such as PE (polyethylene), foam, aluminum foil, etc.

22-400 Aluminum Cap Thread Specifications

The thread characteristics of the 22-400 aluminum cap:

-

Thread Type: Continuous Thread (CT) design

-

Thread Diameter: 22.00mm

-

Thread Characteristics: Fine smooth threads with clear, practical anti-slip teeth.

22-400 Aluminum Cap Surface Treatment and Color Options

Surface Treatment Processes

Common surface treatment methods for the 22-400 aluminum cap include:

- Brushed Silver Finish: Achieved through mechanical brushing, creating a textured pattern on the aluminum cap's surface, giving it a metallic silver appearance.

- Anodizing Treatment: A process in which a layer of oxide film is formed on the aluminum surface through electrochemical oxidation, enhancing corrosion and wear resistance, and allowing for color dyeing.

- Coating Treatment: A protective coating is applied to the aluminum cap's surface to improve corrosion resistance and aesthetics. Common options include transparent and colored coatings.

- Electroplating Treatment: A layer of metal, such as chrome or nickel, is electroplated onto the aluminum cap's surface to enhance its gloss and corrosion resistance.

Color Options

The 22-400 aluminum cap offers a wide range of color options:

- Basic Colors: Silver (natural aluminum color), black, white, and other basic hues.

- Custom Colors: Various colors can be customized according to customer requirements to meet different product packaging needs.

- Effect Colors: Matte, glossy, and metallic finishes are available for special effect color treatments.

-

Silver 22-400 Aluminum Cap

-

Gold 22-400 Aluminum Cap

-

Black 22-400 Aluminum Cap

-

White 22-400 Aluminum Cap

-

Red 22-400 Aluminum Cap

-

Blue 22-400 Aluminum Cap

-

Dark Green 22-400 Aluminum Cap

-

Yellow 22-400 Aluminum Cap

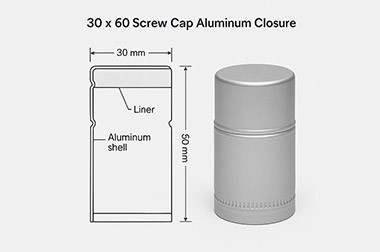

22-400 Aluminum Cap Structure

Overall Structure

The 22-400 aluminum cap features a standard threaded design, consisting of the following main parts:

Top: The flat top portion of the aluminum cap, which can be printed or embossed. Threaded Area: The spiral structure inside the cap, which matches the threads of the bottle neck to form a seal. Skirt: The side portion of the cap, usually with anti-slip ridges or grooves. Liner Groove: The recessed structure inside the cap for installing the sealing liner.

Liner Structure

The liner structure of the 22-400 aluminum cap varies depending on the liner material used:

- PE Liner: Made from polyethylene material, offering good flexibility and sealing properties, suitable for various liquid products.

- Foam Liner: Typically made from expanded polyethylene foam, providing excellent cushioning and sealing effects.

- Pulp and PE Composite Liner: Combines the moisture-absorbing properties of pulp with the sealing capabilities of polyethylene, suitable for moisture-sensitive products.

- Aluminum Foil Liner: Made from metallic aluminum foil, offering excellent barrier properties to effectively prevent liquid evaporation and external gases from entering.

- Pressure-Sensitive Seal Liner: A layer of pressure-sensitive sealing material is attached to the inside of the cap, forming a tight seal when the cap is screwed on.

22-400 Aluminum Cap Features

Physical Properties

- Lightweight and high strength

- Corrosion-resistant

- Good thermal conductivity

- Recyclable

Sealing Properties

- Excellent sealing performance

- Leak-proof design

- Moisture-resistant

- Oxidation-resistant

Usage Characteristics

- Easy to open and close

- Anti-slip design

- Highly adaptable

- Good decorative appearance

22-400 Aluminum Cap Printing Options and Effects

Printing Process Options

The 22-400 aluminum cap can use various printing processes:

- Screen Printing: Suitable for printing large areas of solid color and simple patterns, with high color saturation and a strong 3D effect.

- Offset Printing: Ideal for fine patterns and continuous tones, offering rich color layers and smooth transitions.

- Hot Stamping (Gold/Silver): Uses heat to transfer metal foil onto the aluminum cap, creating metallic patterns or text, enhancing the product's premium feel.

- Laser Engraving: Uses lasers to etch permanent patterns or text on the surface of the aluminum cap, offering excellent anti-counterfeiting effects.

- Embossing/Relief: Uses mechanical pressure to create raised or recessed patterns or text on the surface of the aluminum cap, providing a unique tactile effect.

Printing Effects

Different printing processes offer distinctive effects:

- Screen Printing Effect: Vivid colors, strong coverage, can be printed on both the top and side of the aluminum cap, suitable for bold visual effects.

- Offset Printing Effect: High image precision, good color reproduction, suitable for printing complex patterns and photo-quality images.

- Hot Stamping Effect: Provides a metallic gloss in gold or silver, enhancing the product's premium and high-quality feel.

- Laser Engraving Effect: Creates permanent dark or light patterns, with fine lines, offering excellent durability and anti-counterfeiting properties.

- Embossing/Relief Effect: Forms unique tactile and visual effects through raised or recessed patterns, improving product identification.

22-400 Aluminum Cap Applications

Food and Beverage Industry

- Condiment packaging

- Juice beverage packaging

- Health supplement packaging

- Honey packaging

- Jam and jelly packaging

Pharmaceutical Industry

- Oral liquid bottle packaging

- Tinctures and lotions packaging

- Medicinal essential oil packaging

- Health supplement packaging

Cosmetics Industry

- Perfume packaging

- Lotion and serum packaging

- Essential oils and aromatherapy products

- Creams and ointment products

Other Sectors

- Chemical reagent packaging

- Essential oils and fragrance packaging

- Household cleaning products

- Industrial product packaging

22-400 Aluminum Cap Common Specifications

- 22-400 Silver Aluminum Screw Top Caps (Foam Liner): Silver aluminum screw cap with foam liner, providing excellent sealing and cushioning performance.

- 22/400 Aluminum PE Lined Caps: Aluminum cap with PE material lining, offering good flexibility and chemical resistance.

- 22/400 Aluminum Foil Lined Caps: Aluminum cap with aluminum foil lining, providing excellent barrier properties.

- 22-400 Aluminum Metal Screw Cap with Pulp & Aluminum Liner: Aluminum screw cap with pulp and aluminum composite liner, suitable for moisture-sensitive products.

- 22-400 Aluminum Metal Screw Cap with Heat Seal Liner: Aluminum screw cap with heat seal liner, forming a tighter seal with the bottle neck through heating.

- 22/400 Aluminum Caps with Pressure Sensitive Seal: Aluminum cap with pressure-sensitive sealing liner, providing a good seal with just a light press.

- 22-400 Black Metal Foil Lined Caps: Black aluminum cap with aluminum foil lining, combining aesthetic appeal with excellent barrier performance.

- 22/400 Aluminum Caps with Pulp & Poly Liner: Aluminum cap with pulp and polyethylene composite liner, combining the advantages of both materials.

- 22-400 Silver Threads and Knurled Edge Aluminum Metal Screw Cap: Silver aluminum screw cap with threaded and knurled edges, offering better anti-slip performance.

- 22-400 Aluminum Caps with Expanded Polyethylene Foam Liner: Aluminum cap with expanded polyethylene foam liner, providing excellent cushioning and sealing performance.

22-400 Aluminum Cap Manufacturing Process

Raw Material Preparation

The production of 22-400 aluminum caps begins with the preparation of raw materials:

- Aluminum strip selection: Select 8011-H16 double-sided coated aluminum strips that meet the requirements, ensuring the aluminum cap has good strength and corrosion resistance.

- Liner material preparation: Prepare corresponding liner materials such as PE, foam, and aluminum foil according to different specifications.

- Surface treatment material preparation: Prepare chemical materials for surface treatment, such as anodizing liquids, coating materials, etc.

Forming and Processing

The forming process of aluminum caps includes:

- Stamping: The aluminum strip is stamped into circular cap blanks using a stamping mold, which is the first step in forming the aluminum cap.

- Spinning: The cap blank undergoes spinning to form the required shape and size.

- Thread processing: Special thread processing equipment is used to create a 400 standard thread on the inner side of the cap.

- Knurling: Knurling is applied to the outer skirt of the cap to create anti-slip patterns or grooves, improving usability.

Surface Treatment

To enhance the appearance and performance of the aluminum cap, surface treatments are required:

- Anodizing: An anodized coating is formed on the aluminum surface to improve corrosion resistance and wear resistance.

- Coating: A protective coating is applied to the aluminum cap surface to enhance corrosion resistance and appearance.

- Plating: A layer of metal, such as chromium or nickel, is plated onto the aluminum cap to enhance gloss and corrosion resistance.

- Brushing: A brushing process is used to create fine lines on the surface of the aluminum cap, giving it a unique metallic feel.

Liner Installation

According to different specifications, the installation of the liner is performed:

- PE liner installation: Pre-formed PE liners are inserted into the liner groove of the cap, typically fixed by heat pressing or bonding.

- Foam liner installation: Foam material, cut to the appropriate size, is placed into the liner groove of the cap and typically fixed by pressure fitting.

- Aluminum foil liner installation: Aluminum foil liners are fixed into the cap using special processes, ensuring smoothness and wrinkle-free installation.

- Composite liner installation: For composite liners such as pulp and polyethylene, multi-layer compounding and heat pressing processes are typically used.

Quality Inspection and Packaging

The final stages of production involve quality inspection and packaging:

- Size inspection: Precision measurement instruments are used to check whether the dimensions of the aluminum caps meet the required standards.

- Sealing test: Pressure or leakage tests are conducted to ensure the aluminum caps have good sealing performance.

- Appearance inspection: The surface treatment and printing quality of the aluminum caps are checked to ensure there are no obvious defects.

- Cleaning: The aluminum caps undergo cleaning to remove any oil residue or impurities left from the production process.

- Packaging and storage: Qualified aluminum caps are packaged in specified quantities, typically 1440 caps per carton or other standard packaging specifications.

The following bottle caps may interest you

Further reading : Aluminum ROPP CapBeer Aluminum Anti-counterfeiting Bottle CapLiquor Aluminum CapWhite Aluminum Bottle CapAluminum roll-printing and milling anti-counterfeiting bottle capWine Aluminum CapROPP Aluminum Caps for WaterBeverage Bottle Aluminum CapAluminum Caps for VinegarVodka Bottle Aluminum CapsBlack Aluminum Bottle CapRum Aluminum Screw Caps 30x35mmOlive Oil Aluminum CapAluminum Cap for Whiskey Alcohol Spirit Glass Bottle31.5x24mm embossing and milling Aluminum Cap for Alcohol Whisky VodkaAluminum Bottle Cap 30x60mm for Wine and Spirits Bottles30x35mm Aluminum Bottle Cap for Spirits and Alcoholic Beverages30x43mm Wine Aluminum Cap25x43mm Aluminium Pilfer Proof Bottle Cap30x44mm Aluminum Bottle Cap for Spirits28x18mm Aluminium Closure30x35mm Aluminium ROPP Cap30x60mm Hot Stamping Cover Wine Bottle Lids - Alcohol Whiskey Vodka Aluminum Bottle Cap28mm Beverage Drinks Aluminum Cap38mm Beverage Drinks Aluminum CapBeer Aluminum Bottle CapAluminum anti-counterfeiting bottle capPull-Off Aluminum Bottle CapTamper-Evident Aluminum Bottle Cap28mm Aluminum ROPP Cap28mm Aluminum Cap28x18mm aluminum bottle cap for Vodka28x18mm Aluminium Ropp Cap38mm Aluminum ROPP Cap38mm Aluminum Cap28mm Black Aluminium ROPP Tamper Evident Screw Cap with EPE Liner28mm Silver Aluminium ROPP Cap with Liner28mm 28-400 Aluminum Metal Cap with Pulp & Poly Liner28mm/410 Aluminium Cap with EPE Liner28x15mm Aluminium ROPP Cap26mm 42mm Ring Pull Aluminum Cap30x60mm Aluminum Vodka Tequila Caps30x60mm Aluminum ROPP Caps for Wine Glass BottlesPull Ring Easy Open Aluminum Crown Caps30×60 mm Aluminum ROPP Caps for Whiskey Glass Bottles250 ml Bottles 28×15 mm MCA Aluminum CapsBlue Aluminum Caps33x47mm Side Emboss Aluminum LidsAluminium Pilfer Proof Caps28mm Black Aluminum Screw Top Cap30 x 35 EPE tin liner ROPP Closures30x60mm Aluminum CapAluminium ROPP (18x12)18mm ROPP Aluminum Caps22mm Aluminium Ropp Caps25mm Aluminium Ropp Caps31.5 mm ROPP Aluminum Cap46 mm ROPP Aluminum Cap53 mm ROPP Aluminum CapColored ROPP Aluminum CapsPrinted ROPP Aluminum Caps33x58 Pilfer-Proof ROPP Aluminum Cap38x18mm Aluminum ROPP CapRed 28mm ROPP Aluminum ClosureBrushed aluminium screw caps