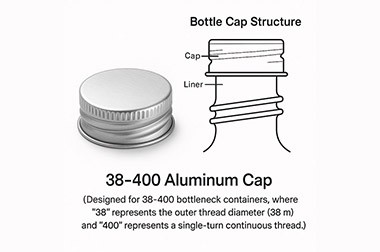

20-410 Silver Aluminum Bottle Cap

The 20-410 standard continuous thread aluminum cap is one of our mature and reliable core products. It is manufactured using high-quality aluminum material and advanced processing techniques, strictly adhering to the internationally accepted 20mm C-410 neck finish standard.

Bottle neck specification 20-410: Standard Continuous Thread (Diameter 20 mm, Thread Pitch 410)

The 20-410 silver aluminum bottle cap is a premium continuous thread closure, precisely designed for sealing 20/410 neck containers. It balances functionality and aesthetics with a brushed silver aluminum shell and integrated PE foam liner, providing an airtight seal. Primary application areas include cosmetics, pharmaceuticals, health and beauty products, and specialty chemicals, where leak-proof integrity and high-end appearance are critical.

- "20": Indicates that this aluminum cap is designed for use with bottle necks that have an outer diameter of 20 mm. This is the key dimensional reference of the cap, determining the inner diameter and thread start position.

- "410": Indicates that the cap uses the 410 specification thread from the C-Line (Continuous Thread) standard. This means:

- Thread Type: Standard Continuous Thread. This is a widely used thread design for bottle necks in packaging for beverages, water, pharmaceuticals, etc., providing reliable tightening and opening functionality.

Thread Parameters: "410" specifically refers to the thread pitch and profile conforming to the industry-defined C-410 standard. This means:

The thread is continuous and evenly spaced.

There are approximately 410 threads per inch of length (converted to a pitch of about 0.062 mm, although this is more of a specification code, and actual production is based on standard molds).

The thread depth, angle (typically 15° or 30°), and shape strictly comply with the C-410 specification to ensure perfect engagement and sealing with standard 20 mm neck finishes.

20-410 Aluminum Cap Material and Surface Treatment

- Bottle Body: Pure aluminum – a corrosion-resistant, rust-proof, and fully recyclable metal.

- Color/Finish: Bright silver or brushed silver for a premium and minimalist appearance.

- Liner: PE/LDPE foam for effective sealing – moisture-proof, leak-proof, and preservative.

20-410 Aluminum Cap Material Composition Table

| Component Part | Material Category | Common Grade/Composition | Performance Characteristics Description |

| Main Cap Body | High-Quality Aluminum-Magnesium Alloy Coil | AA 8011-H24, AA 3003-H24 | Excellent formability: suitable for deep drawing, thread forming, and tamper-evident ring structure forming |

| High strength: withstands tightening torque and internal pressure | |||

| Good ductility: clean break of tamper-evident bridges | |||

| Lightweight: reduces transportation weight and carbon emissions | |||

| Strong barrier properties: oxygen resistance, moisture resistance, and light shielding | |||

| Excellent recyclability: 100% recyclable material | |||

| Sealing Gasket | Food-grade polymer material | See detailed classification below | Embedded or laminated inside the cap body to enhance sealing, leak resistance, and preservation performance |

20-410 Aluminum Cap Sealing Gasket Material Classification

| Gasket Type | Common Materials | Application Scenarios and Features |

| PVC Sol Gasket | Polyvinyl Chloride (PVC) | Low cost, strong adaptability |

| Good conformity to bottle neck curvature | ||

| Suitable for water, juice, edible oil and other liquids | ||

| Injection/Drip Molded Gasket | PE, PP, TPE | Injection molded, strong sealing performance |

| Resistant to internal pressure, suitable for carbonated drinks | ||

| Resistant to flavor migration, suitable for sensitive products | ||

| Foamed PE Gasket | Expanded Polyethylene (EPE) | Good elasticity, strong compensation ability |

| Suitable for bottle necks requiring tolerance compensation | ||

| Commonly used for dry goods, pharmaceuticals, health products, etc. |

20-410 Aluminum Cap Surface Treatment Types and Functional Table

| Treatment Method | Process Description | Functions and Features |

| Anodizing | Forms a dense oxide film on the aluminum surface through electrochemical oxidation | Enhances corrosion resistance |

| Can be colored (silver, gold, black, etc.) | ||

| High-end surface texture | ||

| Spray Coating (UV) | Surface coated with UV-curable paint | Provides matte or glossy effects |

| Enhances visual appeal and tactile feel | ||

| Scratch-resistant and anti-oxidation | ||

| Screen Printing | Uses a screen to print patterns/logos on the aluminum cap surface | Customizable brand logos/text |

| Bright colors, good durability | ||

| Heat Transfer / Hot Stamping | Transfers film/metal foil to the aluminum cap surface using high temperature | Premium texture (metallic luster) |

| Commonly used for perfume and beauty product caps | ||

| Laser Engraving | Precision laser ablation to engrave logos/serial numbers | Anti-counterfeit and traceable |

| Difficult to wear off or tamper with |

20-410 Aluminum Cap Bottle Neck Compatibility and Testing Parameters

| Test Item | Standard or Requirement | Test Description |

| Torque Test | Typical opening torque around 0.8–1.2 N·m (varies by product) | Ensures easy opening but prevents accidental opening |

| Excessive torque may damage the bottle neck, too low may cause leakage | ||

| Sealing Test | Vacuum/liquid leakage test, inverted for 72 hours with no leakage | Uses positive/negative pressure machines to simulate transport and pressure conditions |

| Especially critical for liquid products | ||

| Internal Pressure Resistance Test | For carbonated beverage caps, pressure resistance ≥0.6 MPa (depending on design) | Verifies gas pressure does not cause gasket failure or cap deformation |

| Compatibility Test | No burrs/slipping with 20-410 PET or glass bottles | Variations in bottle neck tolerance among suppliers; compatibility testing recommended |

| Aging and Transport Simulation Test | High temperature and humidity storage, freeze-thaw cycles, vibration and impact tests | Ensures no deformation, leakage, or discoloration during long-term storage/transport |

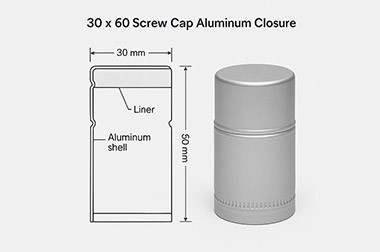

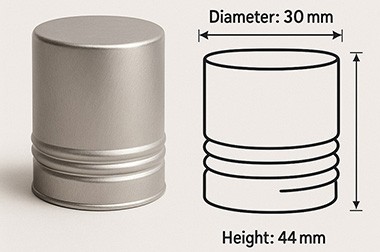

20-410 Aluminum Cap Structure

- Shell: Made of corrosion-resistant aluminum — lightweight, durable, and fully recyclable; rust-free.

- Surface Treatment: Brushed or smooth silver metal for a high-end visual effect. Available in matte, gloss, or embossed textures.

- Liner: Usually PE foam (LDPE or F-217 low-density polyethylene). This compressible liner forms a leak-proof seal at the bottle neck.

20-410 Aluminum Cap Structural Components and Functional Description Table

| Structural Part | Description | Function and Role |

| Top Plate | The flat top surface of the cap, can be color printed, hot-stamped with gold/silver, or retain original anodized aluminum finish. | Main structural support component |

| Provides space for brand display | ||

| Applies vertical pressure to the bottle neck for sealing | ||

| Sidewall / Skirt | Circular structure vertically extended from the top plate, typically 10–15 mm in height, houses the internal thread. | Engages with bottle neck to maintain cap positioning |

| Supports the tamper-evident ring structure | ||

| Provides tactile feel for manual opening | ||

| Thread | Helical internal thread, compliant with C-410 standard (20 mm diameter × 410 pitch). | Enables precise engagement |

| Compatible with automatic capping machines | ||

| Provides reliable sealing | ||

| Supports multiple opening/closing cycles | ||

| Tamper-Evident Ring | Ring structure at the bottom of the skirt, connected by multiple small “bridge points”. These break on first opening, causing the ring to detach. | Provides visible indication of first opening |

| Prevents unauthorized opening or refilling | ||

| Enhances product safety and consumer confidence | ||

| Inner Sealing Surface | Flat area on the inside of the top plate where the gasket adheres, typically smooth finished. | Allows uniform pressure on the gasket for tight bottle neck sealing |

| Prevents localized leakage or seal failure |

Additional Explanation of Thread Structure (410 Standard)

| Key Features | Description |

| Pitch | Single-turn continuous thread with approximately 400 threads per inch |

| Compatible Bottle Neck | Fits standard PET or glass bottle necks with 20mm outer diameter and 410 thread specification |

| Engagement Characteristics | Moderate torque suitable for automatic capping machines and manual consumer operation |

| Interchangeability and Compatibility | Complies with standards platforms such as CPI (Closure & Packaging International) |

20-410 Aluminum Cap Functional Advantages

- Excellent sealing: Precisely matched C-410 thread, flat inner sealing surface, high-quality gasket, and accurate torque control together ensure reliable sealing for liquids (water, beverages, oils), gases (carbonation), and solids.

- Reliable tamper-evidence: The tamper-evident ring design clearly indicates first opening, enhancing product safety and consumer trust.

- Good mechanical properties: Sufficient strength and rigidity to withstand capping machine torque, stacking pressure, and transportation vibration.

- Superior ease of opening: The C-410 continuous thread design provides moderate opening torque for a pleasant consumer experience.

- Wide compatibility: Meets the internationally accepted 20-410 bottle neck standard, seamlessly fitting standard 20mm C-410 bottle necks on the market.

- High production efficiency: Suitable for high-speed automated production lines (cap manufacturing and filling capping lines).

- Attractive and customizable: The top surface can be diversified with printing and decoration to enhance brand image.

- Safe and environmentally friendly: Food-grade materials compliant with relevant regulations (such as FDA, EU) and 100% recyclable.

20-410 Aluminum Cap Applications

- Bottled water: Various specifications of purified and mineral water.

- Carbonated soft drinks: Small bottles of cola, Sprite, etc. (must withstand internal pressure).

- Juice and functional beverages: Small volume packaging.

- Edible oils and condiments: Small bottles of cooking oil, soy sauce, vinegar, etc.

- Pharmaceuticals and health products: Oral liquids, syrups, medicinal bottles (must meet stricter safety and regulatory requirements).

- Personal care products: Small volume trial packs of shampoo, shower gel, etc.

- Other liquid packaging: Such as small packages of industrial chemicals (material compatibility must be confirmed).

HC Aluminum 20-410 Aluminum Cap Quality Control

- Dimensional accuracy: Strict control of critical dimensions such as inner diameter, thread size (pitch, lead, depth), total height, and tamper-evident ring position to ensure perfect fit with bottle necks and smooth machine compatibility. Inspections use precision measuring tools (e.g., projectors, thread gauges).

- Sealing performance testing: Simulates real conditions using negative/positive pressure sealing testers to ensure the cap meets customer sealing level requirements (e.g., no water or air leakage).

- Opening torque testing: Measures the torque required to unscrew the cap, ensuring it is within a reasonable range (neither too tight nor too loose).

- Tamper-evident ring performance: Tests the force required to break the tamper-evident ring and evaluates the condition after breakage (whether it detaches cleanly without burrs), ensuring effective first-opening indication.

- Coating adhesion and corrosion resistance: Tests the resistance of internal coatings to external corrosive media (such as salt spray) and content, as well as the abrasion resistance of printed coatings.

- Gasket integrity: Checks whether the gasket is correctly positioned, free of defects, and firmly bonded to the cap body.

- Appearance quality: Inspects print clarity, color consistency, surface finish, and absence of visible scratches, dents, or oil stains.

The 20-410 standard continuous thread aluminum cap is one of our mature and reliable flagship products. It is manufactured with high-quality aluminum and advanced processes, strictly following the internationally accepted 20mm C-410 bottle neck standard. This cap is favored by many beverage, food, daily chemical, and pharmaceutical manufacturers due to its outstanding sealing performance (especially suitable for water and carbonated drinks), reliable tamper-evident function, smooth opening experience, exquisite printable surface, and efficient production adaptability.

Important note: To ensure optimal performance and sealing, customers must ensure that the glass or plastic bottles they use fully comply with the 20mm C-410 (DCRI) standard when selecting 20-410 aluminum caps. We offer bottle neck compatibility testing services.

The 20-410 silver aluminum cap is designed for performance, compliance, and shelf appeal. It combines the robust seal of a PE foam liner with the stylish design of aluminum, ensuring product integrity across industries. Its low-volume packaging and sustainable materials make it an ideal choice for brands seeking both functionality and quality.

The following bottle caps may interest you

Further reading : Aluminum ROPP CapBeer Aluminum Anti-counterfeiting Bottle CapLiquor Aluminum CapWhite Aluminum Bottle CapAluminum roll-printing and milling anti-counterfeiting bottle capWine Aluminum CapROPP Aluminum Caps for WaterBeverage Bottle Aluminum CapAluminum Caps for VinegarVodka Bottle Aluminum CapsBlack Aluminum Bottle CapRum Aluminum Screw Caps 30x35mmOlive Oil Aluminum CapAluminum Cap for Whiskey Alcohol Spirit Glass Bottle31.5x24mm embossing and milling Aluminum Cap for Alcohol Whisky VodkaAluminum Bottle Cap 30x60mm for Wine and Spirits Bottles30x35mm Aluminum Bottle Cap for Spirits and Alcoholic Beverages30x43mm Wine Aluminum Cap25x43mm Aluminium Pilfer Proof Bottle Cap30x44mm Aluminum Bottle Cap for Spirits28x18mm Aluminium Closure30x35mm Aluminium ROPP Cap30x60mm Hot Stamping Cover Wine Bottle Lids - Alcohol Whiskey Vodka Aluminum Bottle Cap28mm Beverage Drinks Aluminum Cap38mm Beverage Drinks Aluminum CapBeer Aluminum Bottle CapAluminum anti-counterfeiting bottle capPull-Off Aluminum Bottle CapTamper-Evident Aluminum Bottle Cap28mm Aluminum ROPP Cap28mm Aluminum Cap28x18mm aluminum bottle cap for Vodka28x18mm Aluminium Ropp Cap38mm Aluminum ROPP Cap38mm Aluminum Cap28mm Black Aluminium ROPP Tamper Evident Screw Cap with EPE Liner28mm Silver Aluminium ROPP Cap with Liner28mm 28-400 Aluminum Metal Cap with Pulp & Poly Liner28mm/410 Aluminium Cap with EPE Liner28x15mm Aluminium ROPP Cap26mm 42mm Ring Pull Aluminum Cap30x60mm Aluminum Vodka Tequila Caps30x60mm Aluminum ROPP Caps for Wine Glass BottlesPull Ring Easy Open Aluminum Crown Caps30×60 mm Aluminum ROPP Caps for Whiskey Glass Bottles250 ml Bottles 28×15 mm MCA Aluminum CapsBlue Aluminum Caps33x47mm Side Emboss Aluminum LidsAluminium Pilfer Proof Caps28mm Black Aluminum Screw Top Cap30 x 35 EPE tin liner ROPP Closures30x60mm Aluminum CapAluminium ROPP (18x12)18mm ROPP Aluminum Caps22mm Aluminium Ropp Caps25mm Aluminium Ropp Caps31.5 mm ROPP Aluminum Cap46 mm ROPP Aluminum Cap53 mm ROPP Aluminum CapColored ROPP Aluminum CapsPrinted ROPP Aluminum Caps33x58 Pilfer-Proof ROPP Aluminum Cap38x18mm Aluminum ROPP CapRed 28mm ROPP Aluminum ClosureBrushed aluminium screw caps