18-400 Black Aluminum Screw Top Caps

18-400 is a standard thread specification, specifically referring to a bottle neck thread diameter of 18 mm (commonly denoted as the 18-400 series). This specification ensures compatibility and sealing with designated sample bottles. The black aluminum screw top cap is a sealing cap made of aluminum alloy, featuring properties such as lightweight, corrosion resistance, and recyclability. It is typically used in scenarios requiring chemical resistance or high sealing performance, such as laboratories, pharmaceuticals, or premium packaging.

18-400 Black Aluminum Screw Top Caps – Material and Structure

- Aluminum Cap Body: Made from lightweight and durable aluminum material, both interior and exterior surfaces are coated with food-grade protective layers to ensure compatibility with food and cosmetic applications.

- Surface Treatment and Color: Smooth black surface, typically treated with anodizing or spray coating, providing an elegant and consistent appearance—ideal for premium packaging and brand uniformity.

18-400 Black Aluminum Screw Top Caps Technical Specifications

| Parameter | Specification |

| Compatible Vials | 15 mL laboratory vials; 0.5 oz (15 mL) bottles |

| Temp Resistance | Up to 135°C (aluminum liner) |

| Closure Type | Solid top, screw-thread |

| Packaging | Standard pkg of 100 units; bulk pallet options |

18-400 Black Aluminum Screw Top Caps – Neck and Thread Compatibility

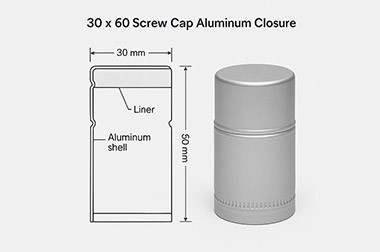

18-400 Thread Size: This cap is suitable for standard 18-400 neck bottles (commonly made of glass or plastic), with a diameter of 18 mm and fine threads (400 series). It is widely used in the pharmaceutical, cosmetic, food, and laboratory supply industries.

Thread Specification and Compatibility

18-400 Thread: This is an internationally standardized bottle neck thread, mainly used to secure sample vial caps (such as 16 mL glass vials), ensuring a tight fit between the cap and bottle mouth to maintain a secure seal. Its design is optimized for compatibility with autosamplers, making it ideal for high-throughput analytical applications.

18-400 Black Aluminum Screw Top Caps – Liner and Sealing Types

- PE (Polyethylene) Liner: Many caps feature molded PE liners that create a tight, leak-proof seal, ideal for 0.5 oz vials to prevent moisture and vapor loss.

- Pulp and Vinyl Liner: Some caps use FDA-compliant layered pulp board/vinyl liners, suitable for weak acids, oils, and aqueous solutions, but not recommended for corrosive hydrocarbons or bleach.

- Rubber, Aluminum, or Polyethylene Sealing Liners: Laboratory-grade caps utilize specialized liners (rubber or polyethylene seals) that can withstand high temperatures and chemicals during sterilization processes.

Liner Comparison

| Liner Type | Advantages | Best For |

| Aluminum | High-temp resilience; inert | Autoclaving, reactive chemicals |

| Poly-Seal/PE | Cost-effective; leak-proof | Non-heated storage, cosmetics |

18-400 Black Aluminum Screw Top Caps – Performance

- Leak-Proof and Spill-Resistant: Features a tight pressure-seal design that prevents spills and contamination when properly tightened.

- Chemical and Heat Resistance: Phenolic/aluminum caps can withstand laboratory environments, autoclaving (up to approx. 135°C), and mildly corrosive substances. PE liners prevent moisture intrusion.

- UV and BPA Considerations: Aluminum surfaces offer UV protection. Some models are BPA-free, though liner safety specifications may vary.

- User-Friendly Design: Ribbed or knurled outer surfaces provide grip, allowing easy opening even with wet hands. Smooth liners ensure proper sealing.

Aluminum Cap Characteristics

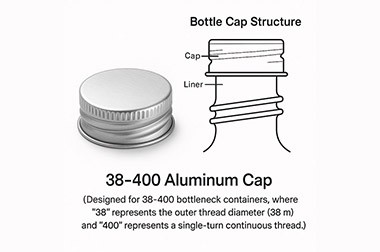

Material and Structure:

- The body is made of aluminum alloy, typically 0.3–0.5 mm thick. The surface can be anodized for enhanced wear and corrosion resistance. The interior may include rubber or silicone liners (e.g., butyl rubber) to improve sealing and prevent gas leakage or contamination.

- The threaded structure is spiral-designed to allow multiple openings and closings without damaging the bottle neck. A torque value of 15–25 N·m is recommended (depending on bottle material) to ensure stability under vibration or temperature variation.

Performance Parameters:

- Pressure Resistance: Can withstand up to 3.0 MPa working pressure, suitable for storing ethylene oxide or volatile chemicals.

- Application Range: Commonly used for essential oil bottles, oral liquid bottles, liquor bottles (e.g., Baijiu caps), and cosmetic dispensing bottles (e.g., aromatherapy bottles), ensuring long-term sealing.

18-400 Black Aluminum Screw Top Caps – Black Surface Treatment and Customization Options

- Color Options: The aluminum cap surface can be made black via electroplating (such as black anodized aluminum) or spray coating, which enhances aesthetics and UV resistance. Some manufacturers offer logo printing services (e.g., laser engraving), supporting brand customization needs.

- Quality Testing: The black coating should withstand 72-hour immersion in 5% salt solution with no corrosion (verified via metallographic microscope). It is recommended to test thread accuracy (cap should screw on and off more than 5 turns smoothly with standard nut).

18-400 Black Aluminum Screw Top Caps – Typical Applications

- Cosmetics and Aromatherapy: Trusted for essential oil roller bottles, sample vials, and cream jars—providing premium appearance and secure sealing.

- Food and Beverage: Ideal for nutritional samples, spice jars, and cooking extracts—liners comply with FDA food-contact regulations.

- Laboratory Use: Compatible with reagent/sample vials (e.g., 15 mL), resistant to solvents and laboratory sterilization cycles.

- Industrial and Health Care: With suitable liners, applicable for small hardware items, spices, and supplements.

Choosing the Right Cap

Liner Type – For general consumer use, select polyethylene (PE) liners;

for mild chemicals, use pulp/vinyl liners.

for high-stability laboratory conditions, choose rubber or polyethylene sealing materials.

Chemical Compatibility – For solvents or acids, opt for phenolic resin or specialized liners.

Heat Sterilization – If autoclaving is needed, ensure the phenolic/aluminum cap and liner can withstand approx. 135°C.

Aesthetic Needs – Aluminum cap bodies offer a premium appearance; black surfaces pair well with dark or amber bottles, helping block UV rays.

The following bottle caps may interest you

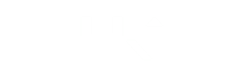

Further reading : Aluminum ROPP CapBeer Aluminum Anti-counterfeiting Bottle CapLiquor Aluminum CapWhite Aluminum Bottle CapAluminum roll-printing and milling anti-counterfeiting bottle capWine Aluminum CapROPP Aluminum Caps for WaterBeverage Bottle Aluminum CapAluminum Caps for VinegarVodka Bottle Aluminum CapsRum Aluminum Screw Caps 30x35mmOlive Oil Aluminum CapAluminum Cap for Whiskey Alcohol Spirit Glass Bottle31.5x24mm embossing and milling Aluminum Cap for Alcohol Whisky VodkaAluminum Bottle Cap 30x60mm for Wine and Spirits Bottles30x35mm Aluminum Bottle Cap for Spirits and Alcoholic Beverages30x43mm Wine Aluminum Cap25x43mm Aluminium Pilfer Proof Bottle Cap30x44mm Aluminum Bottle Cap for Spirits28x18mm Aluminium Closure30x35mm Aluminium ROPP Cap30x60mm Hot Stamping Cover Wine Bottle Lids - Alcohol Whiskey Vodka Aluminum Bottle Cap28mm Beverage Drinks Aluminum Cap38mm Beverage Drinks Aluminum CapBeer Aluminum Bottle CapAluminum anti-counterfeiting bottle capPull-Off Aluminum Bottle CapTamper-Evident Aluminum Bottle Cap28mm Aluminum ROPP Cap28mm Aluminum Cap28x18mm aluminum bottle cap for Vodka28x18mm Aluminium Ropp Cap38mm Aluminum ROPP Cap38mm Aluminum Cap28mm Silver Aluminium ROPP Cap with Liner28mm 28-400 Aluminum Metal Cap with Pulp & Poly Liner28mm/410 Aluminium Cap with EPE Liner28x15mm Aluminium ROPP Cap26mm 42mm Ring Pull Aluminum Cap30x60mm Aluminum Vodka Tequila Caps30x60mm Aluminum ROPP Caps for Wine Glass BottlesPull Ring Easy Open Aluminum Crown Caps30×60 mm Aluminum ROPP Caps for Whiskey Glass Bottles250 ml Bottles 28×15 mm MCA Aluminum CapsBlue Aluminum Caps33x47mm Side Emboss Aluminum LidsAluminium Pilfer Proof Caps30 x 35 EPE tin liner ROPP Closures30x60mm Aluminum Cap22mm Aluminium Ropp Caps25mm Aluminium Ropp Caps31.5 mm ROPP Aluminum Cap46 mm ROPP Aluminum Cap53 mm ROPP Aluminum CapColored ROPP Aluminum CapsPrinted ROPP Aluminum Caps33x58 Pilfer-Proof ROPP Aluminum Cap38x18mm Aluminum ROPP CapRed 28mm ROPP Aluminum ClosureBrushed aluminium screw caps