What is a pilfer proof cap?

May. 12, 2025

Pilfer-proof caps refer to packaging devices specifically designed to prevent unauthorized opening, theft, or accidental opening. Aluminum pilfer-proof caps are made from high-quality aluminum sheets, featuring high-temperature steam resistance, and are commonly used for sealing alcoholic beverages, soft drinks, and pharmaceuticals.

Pilfer-proof caps (commonly referred to as Roll-On Pilfer Proof (ROPP) caps or tamper-evident closures) are specially designed bottle caps intended to prevent unauthorized opening ("pilfering") and to provide clear visual evidence when the seal is broken. They typically include a thin, fragile band or ring that attaches to the bottle neck and breaks when the cap is first unscrewed, making any tampering immediately visible.

Main Functions of Pilfer-Proof Caps

- Anti-theft — Opening requires breaking the security ring, which prevents accidental or opportunistic theft during transportation or on store shelves.

- Tamper-evidence — The removable safety ring provides a clear visual cue indicating the bottle has been opened, enhancing consumer safety and regulatory compliance.

Tamper-Evident Function

The bottle cap contains a breakable security band or perforated ring that breaks upon the first opening of the container. This irreversible breakage signals tampering and alerts consumers to possible interference.

Hybrid Closure Systems

For Roll-On Pilfer Proof (ROPP) caps, the design integrates both threading and crimping mechanisms. A threadless aluminum shell is pressed onto the bottle neck, and rollers form threads around it to create a resealable closure. Upon opening, the perforated band detaches and leaves a visible "skirt" on the bottle neck.

Material Selection: Caps are typically made from durable materials, such as aluminum (for ROPP caps) or plastic (HDPE, polypropylene), to ensure leak-proof seals and corrosion resistance.

Pilfer Proof Cap Design and Mechanism

Roll-On Pilfer Proof (ROPP) Technology

- Initial Form: Smooth aluminum or plastic sleeves with integrated skirt and safety ring.

- Application: On an ROPP capping machine, rollers press the sleeve onto the pre-threaded bottle neck, cold-forming threads into the material and securing the safety ring beneath the cap skirt.

- Separation Mechanism: Thin "bridges" or perforations connect the safety ring to the cap body. When first opened, these bridges break, leaving the ring on the bottle neck and allowing the cap to be removed.

Alternative Designs

- Molded plastic caps with fragile bands: Injection-molded caps may feature a tearable band designed to break at weak points.

- Shrink wrap tamper-evident bands: Separate heat-shrink sleeves wrapped over caps; they tear upon removal and may include perforations or security printing.

Key Features of Pilfer Proof Caps

- Leak-proof sealing: Ensures product freshness and prevents spills.

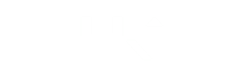

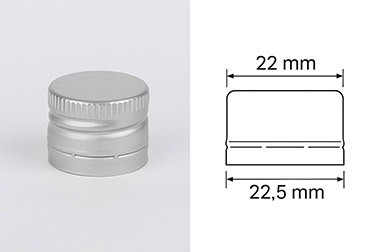

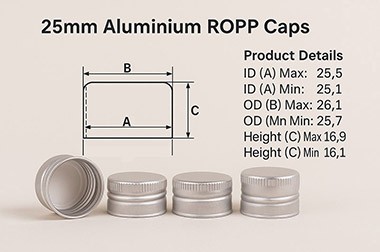

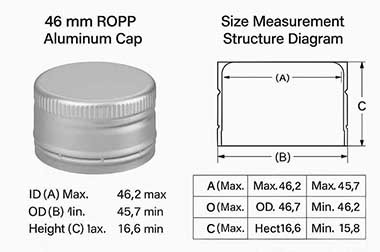

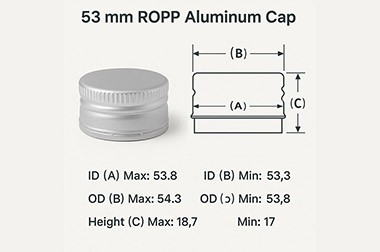

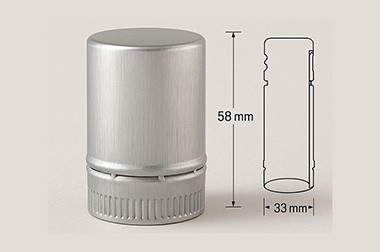

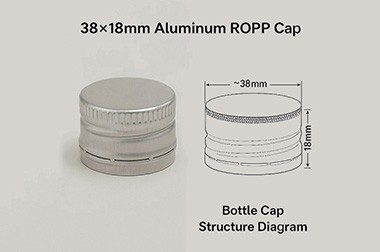

- Customization: Available in a variety of sizes (e.g., 22 mm to 46 mm), colors, and branding options.

- Child safety designs: Some variants include mechanisms to prevent accidental opening by children.

- Anti-counterfeit technology: Advanced caps may incorporate QR codes, RFID tags, or holograms for traceability and authentication.

Pilfer Proof Cap Materials and Variants

- Aluminum: Provides excellent formability for ROPP applications, is lightweight, recyclable, and offers good barrier properties.

- Polypropylene (PP) or Polyethylene (PE): Commonly used in injection-molded tamper-evident caps; can be multilayered to enhance barrier or sealing performance.

- Hybrid Designs: Metal-plastic composites that combine the strength of metal with the flexibility of plastic rings.

Tamper-Evident Features of Pilfer Proof Caps

- Easy-break bridges: Precisely engineered connection points that cleanly shear under torque.

- Security printing: Customized markings or invisible ink on the band that break when tampered.

- Alignment indicators: Raised or embossed marks on the cap or ring that align when sealed; misalignment indicates opening.

Working Principle of Pilfer Proof Caps

- Application: An ROPP cap is placed over the bottle neck. A capping machine uses rollers to form threads into the aluminum shell to match the bottle neck. A paper or plastic liner ensures a tight seal.

- Tamper-evidence: Upon first opening, the safety band breaks and a ring is left behind. This provides a clear visual indication that the cap has been tampered with.

- Reusable seal: The threaded design allows the cap to be reused while retaining its tamper-evident functionality.

Manufacturing Process of Pilfer Proof Caps

Sleeve extrusion or molding – Production of blank caps with ring and skirt components.

- Thread forming – Threads are rolled or pressed onto the cap (for ROPP) or bottle neck (for final engagement).

- Printing and coating – Patterns, varnish, or protective coatings are applied; often UV cured for durability.

- Application – High-speed capping machines synchronize torque and rolling pressure to ensure consistent ring formation and integrity of the safety band.

Applications of Pilfer Proof Caps

- Beverages: Wine, spirits, and carbonated drinks often use aluminum ROPP caps for resealable closure and brand decoration.

- Pharmaceuticals and health supplements: Plastic screw caps with fragile bands meet FDA’s stringent tamper-evidence requirements.

- Household chemicals and personal care products: Detergents, cleaners, and lotions use pilfer-proof closures to protect consumers and retailers.

Advantages of Pilfer Proof Caps over Standard Caps

- Enhanced security: Multi-layer protection prevents tampering and counterfeiting.

- Consumer trust: Visible tamper-evidence reassures buyers of product safety.

- Regulatory compliance: Meets international standards for industries such as pharmaceuticals.

Pilfer-proof caps are indispensable in modern packaging, balancing safety, functionality, and consumer assurance. From ROPP aluminum caps for wine to child-resistant designs for medications, their adaptability and innovation make them a cornerstone of product integrity.

The following bottle caps may interest you