What does ropp stand for in caps?

Apr. 30, 2025

The capitalized ROPP in the packaging industry stands for Roll-On Pilfer-Proof, a tamper-evident bottle cap technology widely used in pharmaceuticals, alcoholic beverages, food, and other packaging.

Roll-On Pilfer-Proof (ROPP) is a tamper-evident closure used for bottles (e.g., in pharmaceutical or alcohol packaging).

Definition of ROPP

Roll-On Pilfer-Proof (ROPP) is a tamper-evident metal (typically aluminum) bottle cap formed through a mechanical rolling process. It provides the following key functions:

- Tamper-evidence: Special structural designs (such as breakable bands and scoring) ensure that once opened, the cap shows obvious physical damage.

- Seal integrity: Offers airtight or leak-proof protection to prevent leakage or contamination of contents.

- Anti-counterfeiting and theft prevention: Prevents unauthorized resealing or content replacement.

ROPP caps are widely used in beverage, pharmaceutical, and specialty liquid packaging. Their design integrates thread forming, tamper-evidence, and sealing functions into one. ROPP stands for "roll-on pilfer-proof," referring to an aluminum cap whose threads are formed directly onto the bottle during the sealing process.

ROPP caps initially appear as smooth, threadless shells. They are pressed using precision capping machines, causing the cap to tightly conform to the bottle's threads, while leaving a detachable tamper-evident band for protection. ROPP caps are made from lightweight, corrosion-resistant aluminum with excellent recyclability, making them ideal for wine, spirits, olive oil, pharmaceuticals, and non-carbonated beverages.

ROPP stands for "Roll-On Pilfer Proof," referring both to its application method (roll-on) and its built-in tamper-evident band.

Structure of ROPP Caps

ROPP closures typically consist of the following components:

- Aluminum shell: A lightweight and malleable metal adapted to bottle necks through rolling.

- Plastic liner: Located inside the cap to provide a sealing cushion (such as food-grade PE or PVC material).

- Tamper-evident band: A scored ring at the bottom of the cap that breaks off upon opening, leaving clear evidence of tampering.

- Rolled-on thread: Threads formed by machinery to match the bottle neck, ensuring tight engagement.

ROPP Cap Application Mechanism

- Placement: A smooth cap blank is placed over the bottle neck, aligning the skirt with the container surface.

- Thread forming by rolling: Rollers on the ROPP capping machine rotate and press around the cap, cold-forming threads into the aluminum and embedding the cap into the bottle’s existing thread mold.

- Tamper band formation: Perforations at the bottom skirt of the cap remain uncurled, forming a tamper-evident band that engages when opened for the first time.

- Airtight sealing: The combined action of mechanical curling and liner compression creates a leak-proof, airtight seal for liquids and volatile substances.

Advantages of ROPP

| Feature | Description |

| Tamper-evidence | The breakable band design ensures irreversibility after opening, eliminating resealing. |

| High sealing performance | Airtight/liquid-tight performance exceeds that of ordinary plastic caps, extending shelf life. |

| High production efficiency | Automated rolling equipment enables high-speed capping (hundreds of bottles per minute). |

| Environmental friendliness | Aluminum is recyclable and aligns with sustainable development trends. |

| Brand enhancement | Metallic texture elevates product quality perception, commonly seen in luxury packaging. |

Working Principle and Sealing Process of ROPP Caps

- Preformed shell: The aluminum cap starts as a cylindrical blank with no threads.

- Rolling formation: High-speed rotating rollers press the aluminum cap tightly onto the bottle neck, forming threads that match the bottle perfectly.

- Tamper band activation: When the bottle is opened, turning the cap causes the tamper band to break at the scored lines and detach, indicating it has been opened.

Features of ROPP Closures

- Tamper-evident: The removable tamper-evident band clearly shows whether the container has been opened before purchase.

- Leak-proof performance: Ensures liquid seal integrity during transport and storage, regardless of carbonation.

- On-site thread forming: Eliminates the need for pre-threaded caps, simplifying mold logistics and enhancing flexibility.

- Recyclability: 100% aluminum structure supports circular economy and sustainability goals.

How to Identify ROPP Caps?

- Observe the Break Ring: After opening the bottle, a break ring or detachment trace remains below the bottle neck.

- Roll-On Marks: The cap surface has uniform threads or corrugations formed by machine rolling.

- Material Feel: Tapping the cap produces a metallic sound, and the texture is harder (distinguishing it from plastic caps).

ROPP Cap Applications

- Wine and Spirits: Employs professional surface treatment and tamper-evident features to securely seal high-quality glass bottles.

- Pharmaceuticals and Health Products: Ensures the safety of syrups, suspensions, and laboratory reagents where product integrity and hygiene are critical.

- Olive Oil and Vinegar: Preserves flavor and aroma by preventing oxidation and leakage.

- Non-Carbonated Beverages: Juices, flavored water, and nutritional drinks benefit from secure sealing without gas retention issues.

| Application Field | Specific Use | Description |

| Pharmaceuticals | Medicine bottles, vaccine vials | Ensures drug safety and prevents contamination |

| Alcoholic Beverages | Premium spirits (such as whiskey, vodka), wine | Replaces traditional corks, enhances sealing and anti-theft performance |

| Food | Olive oil, juice, sauces, and other products requiring long-term sealing | Maintains product freshness and prevents leakage and contamination |

| Cosmetics | Perfumes, serums, and other high-value liquid products | Enhances packaging texture and ensures safe storage of contents |

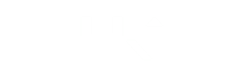

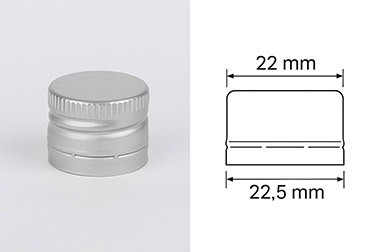

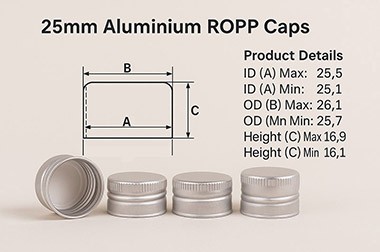

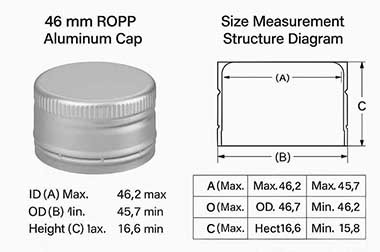

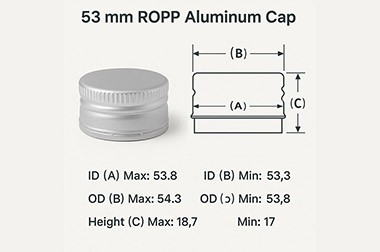

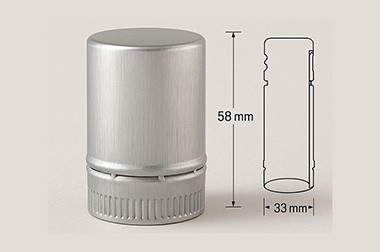

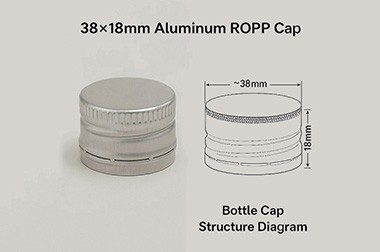

ROPP Cap Sizes and Standards

- Common Diameters: Range from 18 mm to 38 mm. Popular sizes include 28 mm and 30 × 60 mm, suitable for wine and spirits.

- Machine Compatibility: ROPP capping heads are typically interchangeable among rotary or inline capping systems for different cap sizes, but changing heads requires precise mold adjustment.

ROPP Cap Advantages and Limitations

Advantages of ROPP Caps

- Integrated Tamper-Evidence: Enhances consumer safety and brand trust without the need for additional materials or liners.

- High Throughput: Modern rotary ROPP capping systems can cap hundreds to thousands of bottles per minute.

- Cost-Effective: Compared to molded caps, aluminum blanks are cheaper, and sealing is completed in a single step, reducing operational complexity.

Limitations of ROPP Caps

- Equipment Investment: ROPP capping machines require precise mechanical structures, making them a higher investment than simple screw capping systems.

- Bottle Material Restrictions: Requires rigid, hardened bottle necks (glass or engineering plastic) to withstand pressing force without deformation.

- Size Conversion: Changing cap diameters requires downtime to replace caps and adjust the machine.

ROPP (Roll-On Pilfer-Proof) is a key technology in the packaging industry. Through metal rolling processes and break ring design, it ensures product safety while enhancing brand value. Its core value lies in "once opened, permanently marked," making it the preferred sealing solution for pharmaceuticals, alcoholic beverages, and other products requiring high security.

The following bottle caps may interest you