ROPP Cap Aluminum Foil 8011

Jun. 20, 2025

ROPP (Roll-On Pilfer-Proof) cap aluminum foil is primarily made from 8011 aluminum alloy, a material specifically designed for anti-counterfeit roll-on bottle caps. It is widely used in the packaging of alcoholic beverages (such as red wine and white spirits), pharmaceuticals, cosmetics, and food.

ROPP Cap Aluminum Foil 8011 Data Sheet

| Feature | Specification |

| Alloy | 8011 (±3105/8079 variants) |

| Temper | H14 primarily; sometimes H16/H18 etc. |

| Thickness | ≈0.15–0.30 mm (typical 0.17–0.25 mm) |

| Width | 300–1,200 mm+ |

| Tensile Strength | 130–170 MPa |

| Elongation | ~1–3% |

| Coating | Lacquer or color epoxy; one or both sides |

| Key Uses | ROPP bottle caps (wine, beverage, pharmaceutical) |

ROPP Cap Aluminum Foil 8011 Material and Temper

- Alloy: 8011 (commonly used; sometimes mixed with 3105/8079); ensures excellent formability and low earing rate (<3%)

- Temper: H14 is the most common (semi-hard, strain-hardened, partially annealed), with H16, H18, H24, and H26 also available upon request

ROPP Cap Aluminum Foil 8011 Thickness and Width

- Thickness ranges approximately from 0.15 to 0.30–0.45 mm; commonly used range is 0.17–0.25 mm.

- Width ranges from approximately 300 mm to 1200 mm or even wider, depending on the coil.

ROPP Cap Aluminum Foil 8011 Surface Treatment and Coating

One-side or two-side coated (epoxy lacquer, FDA-approved) for printing, sterilization resistance (up to 121°C steam or 180°C baking), and corrosion resistance.

Colored coatings: gold, white, red, blue, black, etc.; coating weight:

- Gold/yellow: 5–6 g/m² on both sides, 2–3 g/m² on one side

- Other colors: 10–13 g/m².

Mill finish surface treatment options: chromated, DOS oil lubricated, or plain.

ROPP Cap Aluminum Foil 8011 Tolerances

- Thickness range: 0.15–0.25 mm, ±0.005 mm; thickness >0.25 mm, ±0.01 mm.

- Width tolerance +0/ +0.5 mm (≤800 mm), up to +1 mm for wider widths.

ROPP Cap Aluminum Foil 8011 Forming and Performance

- Excellent deep-drawing performance, capable of forming complex long-neck closures while maintaining flatness and minimizing defects.

- Usually only the inner side is coated (e.g., for Omnia caps) to avoid interaction with internal gaskets.

- Coated caps include EPE (polyethylene) liners for tamper-evident sealing, leak prevention, and shelf life extension.

- Formability: Optimized for deep-drawing forming of ROPP (Roll-On Pilfer-Proof) caps.

- Barrier properties: Blocks light, oxygen, and moisture to maintain product integrity.

- Corrosion resistance: Inert to acids and alkalis in pharmaceuticals and food.

ROPP Cap Aluminum Foil 8011 Applications

Widely used across industries for sealing bottles:

- Wine and spirits (long-neck ROPP)

- Carbonated and non-carbonated beverages

- Pharmaceutical bottles, oral liquids, syrups

- Cosmetics, medical, and food can closures.

Application Scenarios

| Application Field | Typical Products | Performance Advantages |

| Alcohol Bottle Caps | Wine capsules, liquor caps, screw caps | Tamper-evident sealing (with perforation break line design), light-blocking and freshness preservation |

| Pharmaceutical Packaging | Medicine bottle caps, PTP blister foil, cold-formed pharmaceutical foil | Sterile sealing, high heat-seal strength |

| Food Packaging | Milk cap foil, easy-peel yogurt lid, milk powder caps | Easy-peel design, hygienic and safe |

| Daily Chemical Packaging | Cosmetic bottle caps, easy-open lids | Printable surface for exquisite designs to enhance product appeal |

Main Applications in the Packaging Sector

- Beverage Bottle Caps: Mainly used for wine/liquor bottles; can replace plastic caps, saving up to 50% in cost and is fully recyclable.

- Pharmaceutical Sealing: Compatible with epoxy/polyester coatings (e.g., single-sided gold coating); suitable for flip-off seals and tamper-evident closures for medicine bottles. Resistant to high-pressure sterilization and tested with HgCl₂ to ensure sterility.

- Food Packaging: Yogurt lids, dairy seals, and heat-seal foil (thickness 0.025–0.05 mm), compliant with FDA/SGS food safety standards.

- Industrial Uses: Transformer winding tape and cable shielding layers.

ROPP Cap Aluminum Foil 8011 Chemical Composition

Composition: Al ~97–98.9%, Fe 0.6–1.0%, Si 0.4–0.9%, Mn ≤0.2%, trace elements such as Cu, Mg, Ti, Cr.

8011 aluminum foil is an aluminum-iron-silicon alloy characterized by a precisely balanced elemental composition. The main components include:

- Aluminum (Al): 97.3–99.1% (main component)

- Iron (Fe): 0.6–1.0% (enhances strength and reduces tearing)

- Silicon (Si): 0.5–0.9% (improves formability and surface finish)

- Trace elements (Cu, Mn, Mg, Cr, Zn, Ti): Each ≤0.1% (total ≤0.15%)

ROPP Cap Aluminum Foil 8011 Mechanical Properties

- Tensile Strength: 120–160 MPa (varies by temper)

- Yield Strength: 120–135 MPa

- Elongation: 2.5–4%

- Earring Rate: 0–2% (critical for deep-drawing caps without deformation).

Why Choose 8011 Alloy for ROPP Aluminum Caps?

- Excellent deep-drawing performance, low earing, and good lacquer adhesion.

- High corrosion resistance, reliable formability, and recyclability.

- Food-grade safety with lacquer options that meet FDA standards, along with outstanding light-blocking, moisture-proof, and oxygen-resistant properties — all crucial for food, pharmaceutical, and beverage packaging.

ROPP Cap Aluminum Foil 8011 Manufacturing Specifications

| Parameter | Specification Range | Key Applications |

| Thickness | 0.016–0.4 mm (common: 0.17–0.22 mm) | Pharma caps (0.17–0.22 mm) |

| Width | 30–1,600 mm | Standard caps: 449–796 mm |

| Temper Options | H14, H16, H18, O | H14/H16 for coated caps |

| Surface Treatment | Clear/golden lacquer, bare, or double-sided coating | Protective lacquer for medical seals |

Quality Control Indicators:

- Thickness tolerance: ±0.005 mm

- Surface integrity: No rolling marks, scratches, or stains.

Advantages of ROPP Cap Aluminum Foil 8011 Compared to Other Materials

Compared to plastic caps:

- Cost: Production costs reduced by 50%.

- Sustainability: Fully recyclable; reduces microplastic pollution.

- Performance: Excellent sealing integrity and tamper-evident features.

Compared to 3003/1050 alloys:

- Formability: Lower earing rate (0–2% versus 3–5% for 3003 alloy).

- Durability: Higher iron-silicon ratio enhances anti-tear performance during capping.

Selection Criteria for Specific Uses

- Pharmaceutical/Alcohol Bottle Caps: Specified thickness 0.17–0.22 mm, H14/H16 temper aluminum foil with epoxy coating. Verified by high-pressure sterilization and acetone tests.

- Food Sealing: Uses O temper aluminum foil (0.025–0.05 mm) with FDA-compliant heat-seal layer. Ensures high temperature resistance (-50°C to 260°C).

- High-speed Capping: Prefer H18 temper aluminum foil with tensile strength >150 MPa and elongation ≥3%.

ROPP Cap Aluminum Foil 8011 is an industry benchmark for safe and sustainable packaging, combining unparalleled deep-drawing capability (≤2% earing rate), compliance (FDA/SGS), and cost-effectiveness. Its dominance in the pharmaceutical and beverage markets stems from its unique iron-silicon alloy design, precisely convertible into tamper-evident seals. With increasing circular economy demands, the recyclability of 8011 will further replace plastics and be enhanced by innovations in ultra-thin gauges and functional coatings.

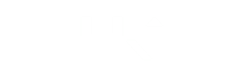

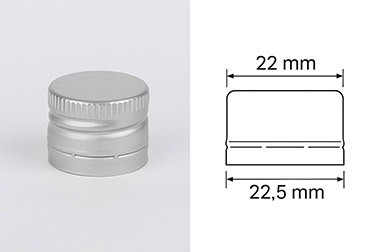

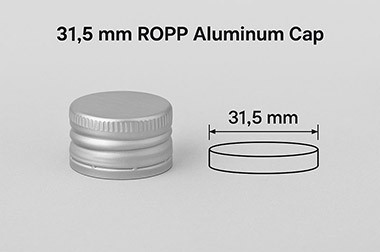

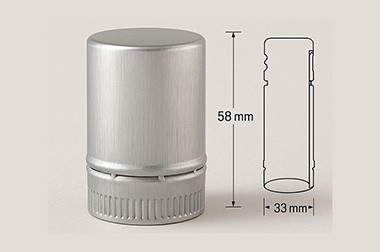

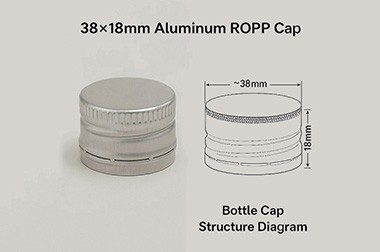

The following bottle caps may interest you