Pilfer Proof Closures

Jun. 10, 2025

Pilfer-proof closures (also known as tamper-evident closures) are specially designed bottle caps that clearly indicate if a container has been opened.

Pilfer proof closures are specialized packaging components designed to provide tamper evidence and prevent unauthorized access to the contents of a container. These closures use carefully engineered failure mechanisms that result in irreversible physical changes, visibly indicating any attempt to open them. Unlike standard caps, pilfer proof closures leave tamper evidence through broken bands, fractured bridges, or permanently deformed components. This security feature is critical in industries where product integrity directly affects consumer safety and brand reputation—particularly in pharmaceuticals, beverages, and high-value consumer goods.

What Makes a Closure "Pilfer-Proof"?

Tamper-Evident Band/Break Ring

A perforated or frangible ring at the base of the cap breaks or detaches when the cap is first twisted open. It remains on the bottle or cap, providing a visual indication of tampering.

Ratchet or Locking Mechanism

Featuring toothed structures ("ratchet caps") that prevent the cap from returning to its original position after opening, making re-sealing clearly noticeable.

Roll-On Pilfer Proof (ROPP)

During the capping process, an aluminum sleeve is placed over the bottle neck and threaded using rollers. The perforated band at the bottom of the sleeve breaks upon the first opening.

Induction Seal and Liner (not always part of the cap itself)

A heat-activated foil or plastic seal inside the cap must be punctured or removed to access the contents—again providing proof of opening.

Internal Latches/Locks

Plastic caps may include internal flexible latches that snap under the bottle neck. When the connection is broken, it indicates tampering.

Core Structural Components and Design Features of Pilfer Proof Closures

- Top: The main cap that seals the container opening, usually containing a liner (PE, EPE, silicone, or butyl rubber) to ensure tight sealing.

- Skirt: The cylindrical section extending downward from the top, with threads that engage the neck of the container. In metal caps, this includes a fracture line (a perforated "bridge line") designed to break upon first opening.

- Locking/Tamper-Evident Band: The lower section beneath the fracture line, equipped with elastic locking features (inward lips or tabs). After opening, this band remains on the container neck.

- Thread Formation: In Roll-On Pilfer Proof (ROPP) caps, threads are formed during the capping process by a capping machine, which uses rotating rollers to press the unthreaded aluminum shell onto the bottle neck.

| Component | Metal ROPP Closures | Plastic Closures |

| Tamper Ring | Breakable bridges connecting skirt | Pre-formed frangible bands |

| Thread Formation | Roller-formed during application | Pre-molded during manufacturing |

| Locking Mechanism | Inwardly displaced lips engaging container rim | Snap-fit beads under container collar |

| Material Thickness | 0.20-0.23mm aluminum | 1.0-1.5mm plastic polymers |

Typical Components of Pilfer Proof Closures

- Closure Body: Threaded or roll-on design; made of plastic or metal.

- Tamper-Evident Band: Connected by thin bridges below the closure; breaks upon first twist.

- Internal Features: Locking tabs, ratchet teeth.

- Liner and Seal: Foil or conical liner providing additional protection against contamination.

- Branding Elements: Embossing, coloring, and custom printing to verify authenticity and secure brand licensing.

How It Works: Opening a Pilfer Proof Closure

First Use:

Twist the closure; the tamper band breaks (visible), internal pull tabs detach, and the seal is compromised—this serves as evidence of tampering.

After Opening:

The broken tamper band is visible; resealing is possible, but signs of tamper-evidence system damage remain clearly noticeable.

Pilfer Proof Closures Materials and Manufacturing

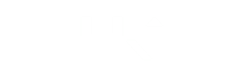

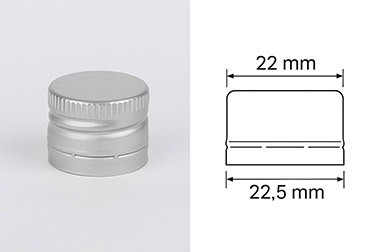

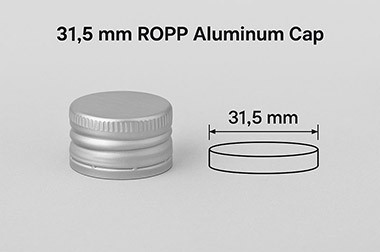

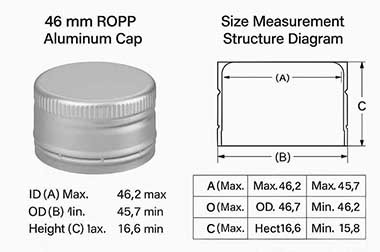

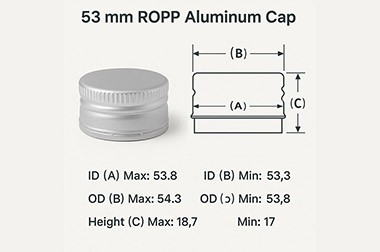

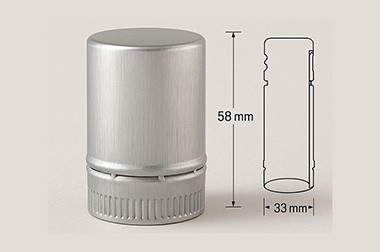

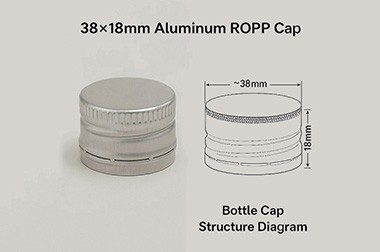

- Aluminum ROPP Closures: Manufactured from ductile aluminum (typically 99.7% purity), supplied as pre-formed shells in standard diameters (18mm, 22mm, 28mm, 30mm, 40mm). Available in various finishes including gold, silver, rose gold, and custom colors .

- Plastic Closures: Injection-molded from polypropylene or polyethylene in standard colors (white, light/dark blue, green, red, yellow, black), often with liner inserts .

Aluminum Pilfer-Proof Cap

Made from specialized aluminum sheets, resistant to high-temperature sterilization, mainly used for sealing alcoholic beverages, carbonated drinks, and oral liquids.

The typical structure includes a tamper-evident ring and threaded design; when opened, the ring breaks, providing clear evidence of tampering.

Plastic Pilfer-Proof Cap

Made from polyolefin materials using injection molding or compression molding processes. The top is equipped with an annular leak-proof ring or used in combination with an inner cap.

The lower part connects the tamper-evident ring through tension-enhancing ribs. Helical tension wings are distributed along the inner wall, ensuring a secure seal and leaving visible damage marks after opening.

Suitable for beverages, chemicals, and pharmaceuticals. The sealing performance must be tested using positive pressure sealing instruments.

Manufacturing process: Metal caps are formed using deep drawing, while plastic caps are produced via high-precision injection molding. The key for both lies in designing controlled failure points in micro-perforated or thin-walled areas.

Tamper-Evident Mechanisms of Pilfer Proof Closures

- Bridge Fracture System: A series of micro-bridges (usually 8–24) connect the skirt of the cap to the locking ring. During opening, when torque exceeds 5–15 Nm, these bridges break, permanently securing the locking ring under the locking edge of the container.

- Locking Ring Engagement: The locking ring features inward-projecting lips that snap under the bead of the container during use. Once engaged, these lips prevent the ring from falling off without the need for destructive force.

- Visual Indicators: Effective tamper-evidence requires clear separation indicators—dangling plastic rings, detached metal rings, or visibly broken bridge points. The design utilizes optimized thread geometry to prevent "spinning" (cap rotation without bridge breakage).

Pilfer Proof Closures Common Closure Types and Use Cases

| Closure Type | Material | Application | Tamper-Evidence |

| Plastic Screw Caps | HDPE/PP | Beverages, FDA-approved products | Band, tear bridges, ratchet teeth |

| Aluminum ROPP | Aluminum | Spirits, oils, pharma | Roll-formed band |

| Plastic with Internal Tabs | PP/PE | Pharmaceuticals, chemicals | Snapped tabs |

| Lined Plastic Caps | Plastic + liner | Condiments, dairy | Induction cap-seal/external band |

Industry Applications and Standards of Pilfer Proof Closures

- Pharmaceuticals: 28–30 mm closures for oral liquid/syrup bottles; liners must be compatible with contents (butyl rubber for steam, silicone for inert substances).

- Beverages: 40 mm closures for wine/spirits bottles; aluminum provides oxygen barrier, aiding in preservation.

- Food and Chemicals: 18–22 mm closures for oil/vinegar bottles; capable of withstanding sterilization processes.

- Compliance: Meets ISO 9001/14001/13485 standards and certified under ISCC PLUS sustainability scheme.

Technical Advantages and Limitations of Pilfer Proof Closures

Industry Advantages of Pilfer Proof Closures

- Superior tamper-evident performance compared to standard screw caps.

- Aluminum materials offer excellent barrier properties.

- Resealability enabled through upper thread engagement.

- Consumer safety and trust: clear indication of product integrity.

- Regulatory compliance: mandatory for pharmaceuticals, food, and beverages.

- Product integrity: ensures sealed and locked condition before first use, preventing leaks or spills.

Industry Limitations of Pilfer Proof Closures

- Higher equipment costs.

- Container necks must withstand forming pressure (limited to glass/hard plastic).

- Limited color options for uncoated aluminum.

- Plastic materials offer lower gas barrier performance.

Comparison of Pilfer Proof Closures with Other Caps

Unlike pre-threaded continuous thread (CT) screw caps, ROPP closures:

- Require mechanized operation (not suitable for manual application).

- Provide integrated tamper-evident function without needing separate sealing.

- Offer superior tamper protection with durable adhesion between metal and glass.

- Enable faster production but require molds dedicated to specific containers.

Quality Assurance and Manufacturing of Pilfer Proof Closures

- Manufacturing involves injection or compression molding with integrated perforation lines.

- To ensure consistent breakage characteristics.

- Torque testing verifies that the force required to open matches design specifications, preventing accidental breakage or false positives.

- Material selection (PP, HDPE, aluminum) balances cost, safety, recyclability, and sealing performance.

The following bottle caps may interest you