What is the difference between a flip cap and a screw cap?

Apr. 23, 2025

Flip caps (also known as top flip or snap caps) and screw caps (also known as twist-in or screw-off caps) differ primarily in opening mechanism, sealing performance, user ergonomics, and ideal applications.

Flip caps use a hinged lid that opens with a flipping motion and closes with an audible snap, allowing quick one-handed operation and precise dispensing.

Screw caps rely on matching threads on the cap and container neck to screw on and off, providing a tighter seal—often enhanced with liners or tamper-evident rings—for long-term storage and transport.

Flip caps excel in ease of use and controlled dispensing, but offer inferior leak resistance compared to screw caps. Screw caps can incorporate EPE, PS, or induction seal liners to prevent air, moisture, and contamination. Manufacturing considerations and cost further differentiate the closures: screw caps are typically simpler and cheaper for mass production, while flip caps require molded hinges but reduce part loss when affixed to containers.

Flip Cap

A flip cap consists of two main components: a base with an integrated nozzle or orifice and a lid with a hinge that flips upward and snaps back down to close. The hinge is typically a thin, flexible section formed from the same plastic material (usually polypropylene or polyethylene) during molding, offering durability and low-cost production.

Flip Cap Materials and Structure

Most flip caps are injection-molded from food-grade plastics such as PP or HDPE, which offer chemical resistance, durability, and suitability for living hinges. Additionally, flip caps may also be made of metal, such as stainless steel or aluminum, for applications requiring higher durability or aesthetic appeal.

Typical Applications of Flip Caps

Flip caps are commonly used in products requiring frequent and controlled dispensing, such as shampoos, lotions, and hand sanitizers in personal care, as well as condiments and sauces in the food industry.

Screw Cap

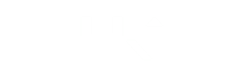

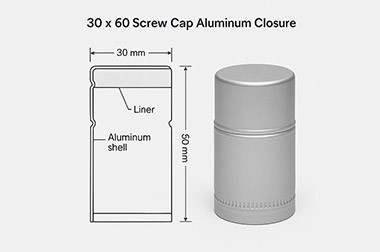

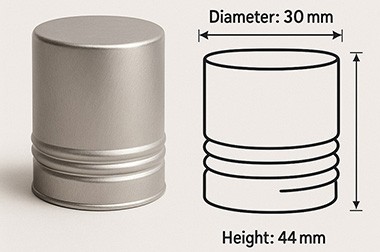

Screw caps are characterized by cylindrical caps with internal threads that engage with external threads on the container neck; users tighten them by rotating clockwise and remove them by rotating counterclockwise.

Sealing Integrity and Liners

To enhance sealing integrity, screw caps typically incorporate sealing liners such as EPE (expanded polyethylene), PS (pressure-sensitive), or IHS (induction heat seal), which press against the container edge or fuse to it under induction to prevent leakage and contamination.

Tamper-Evident and Safety Features

Screw caps can be equipped with tamper-evident rings or tear bands that provide visual evidence of first opening, and may also be designed as child-resistant closures requiring push-and-turn or squeeze mechanisms.

Typical Applications of Screw Caps

Screw caps are widely used for beverage bottles (water, soda), jars (jams, pickles), pharmaceuticals, and chemicals—applications where strong sealing and tamper evidence are critical.

Flip Cap vs. Screw Cap Key Differences

| Category | Flip Cap | Screw Cap |

| Opening Mechanism | Hinged lid flips open at a fixed point and snaps shut with a click | Rotating threaded engagement, must align and twist to open or close |

| User Convenience | Operable with one hand, lid stays attached to bottle after opening, ideal for on-the-go use | Usually requires two hands; some designs include textured grips or large diameter for easier opening |

| Dispensing Control | Often features small holes or spouts for flow control, drip prevention, and precise dosing | Larger openings allow fast pouring but less control; some versions include spouts or pour rings for better handling |

| Sealing and Leak Resistance | Typically includes internal seal structures; relies on snap fit with bottle mouth; hinge or latch failure may cause leakage | Tight thread engagement, may include liners or gaskets for enhanced leak-proof and airtight performance |

| Manufacturing and Cost | Requires precise mold for hinge and latch structure, more complex design, higher unit cost; no need for extra tethers or labels | Simpler mold design, suitable for mass production, lower cost; widely used for beer bottles, easy to clean |

Flip Cap vs. Screw Cap Advantages and Disadvantages

| Feature | Flip Cap | Screw Cap |

| Convenience | One-hand, quick access | Two-hand twist, slower access |

| Seal Quality | Moderate; relies on snap fit | High; threaded + liner |

| Dispensing Control | Precise drip-free flow | Faster pour, less control |

| Leak Resistance | Vulnerable if hinge wears | Excellent with liners |

| Cost | Higher mold complexity | Lower per unit, mass production |

| Sustainability | Tethered, less litter | Removable, potential loss |

| Tamper Evidence | Optional seals; less common | Common rings or induction seals |

Flip caps and screw caps each have their own advantages and disadvantages. Flip caps prioritize user convenience, controlled dispensing, and waste reduction, making them ideal for high-frequency use products such as personal care items and condiments. Screw caps offer superior sealing performance, tamper-evident features, and cost-effective mass production, making them well-suited for the packaging of beverages, jars, chemicals, and pharmaceuticals.

The following bottle caps may interest you