Understand the diameter of the neck of the glass bottle

Jun. 12, 2025

To determine the diameter of the bottle cap, please measure from one side of the inner wall to the other side. Measure the diameter of the outermost thread to calculate the bottleneck. The resulting millimeter measurement is the "T" dimension.

Number of Turns of the Bottle Cap Thread

Quick Reference Table

| Turns | Finish Code | Characteristics |

| 1 | 400 | Standard single turn |

| 1.5 | 410 | Most common continuous thread |

| 2 | 415 | Two turns, tall neck |

| 2 | 425 | Two turns, narrow threads |

| — | 430 | Buttress finish (deep threads) |

| — | 2000+ | Lug finish (non-continuous) |

| GPI Finish Code | Image | Key Parameters & Description | Thread Type | Turns | Thread Pitch (TPI) | Sealing Location | Common Use & Features |

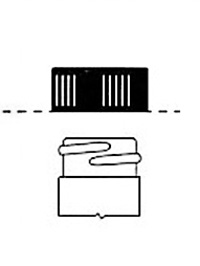

| 24-410 |

|

"T" Dimension: 24mm inner bore diameter | Continuous Thread | 1.5 turns | 10 TPI | Usually seals on top edge | Common food jar finish (e.g., jam, salsa) |

| Standard continuous thread finish | |||||||

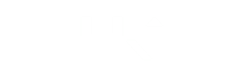

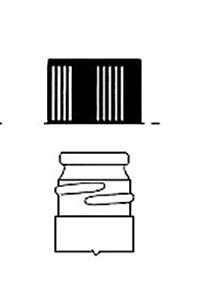

| XX-400 |

|

Continuous thread finish | Continuous Thread | 1 turn | 8 TPI | Usually seals on top edge | Older style, less common than 410, often used for chemical bottles |

| Older style, coarser threads | |||||||

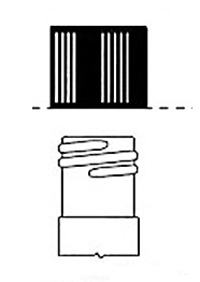

| XX-415 |

|

Continuous thread finish | Continuous Thread | 2 turns | 8 TPI | Usually seals on top edge | Requires taller cap, used for wider mouth products like some nut butter jars |

| Taller "H" dimension (overall glass finish height) | |||||||

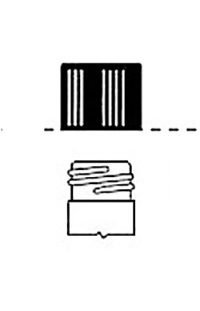

| XX-425 |

|

Continuous thread finish | Continuous Thread | 2 turns | 8 TPI | Usually seals on top edge | Similar applications as 415 |

| Narrower/thinner thread profile | |||||||

| XX-430 |

|

Buttress thread finish (asymmetric profile: steep and shallow sides) | Buttress Thread | 2 turns | 6 TPI | Seals on top bead | Used in pressure applications (e.g., carbonated beverages like beer, soda), very secure seal |

| Thick, wide threads | |||||||

| Top bead present | |||||||

| XX-2000 |

|

Lug finish (3,4, or 6 lugs instead of continuous thread) | Lug Finish | Less than 1 turn (¼ to ½ turn) | N/A | Cap lugs engage under glass lugs | Twist-off caps for beverage bottles (e.g., beer, soda, ready-to-drink teas) |

| Cap has matching lugs; placed and turned less than a full rotation to lock |

How to Actually Identify a Bottle Finish

Measure the "T" Dimension: Use digital calipers to get the inner bore diameter (ID) in mm.

Visually Identify Key Features:

- Continuous thread? Lug? (Non-continuous).

- Approximate number of thread turns (1, 1.5, 2)? (For continuous thread).

- Is there a prominent top bead? (Indicates 430 or similar).

- Are the threads thick/buttress shaped? (Indicates 430).

- Measure Thread Pitch (Optional but helpful): Use a thread pitch gauge (Imperial - TPI) to measure the number of threads per inch on a continuous thread finish.

- Result: You get the full finish designation (e.g., 24-410, 28-400, 38-430, 43-2000).

The "bottleneck size" for capping is defined by the GPI Finish Designation (e.g., 24-410).

T Dimension = Inner Bore Diameter (mm). Measure with calipers.

Finish Code (e.g., 410) = Standardized code defining thread type, turns, pitch, and sealing surface. Determined by visual inspection and comparison to standards.

The fraction-like notation (e.g., 24/410) is simply shorthand for the full GPI finish designation 24-410, combining the T-dimension and the finish code. The denominator (410) is not a measurement you take directly; it's a code representing the thread design specifications.